The Cobra Crusher can turn a handful of 1-inch rocks into fine powder in just seconds.

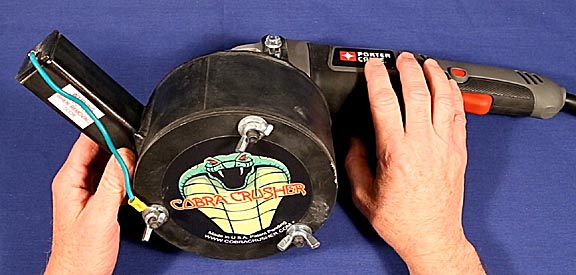

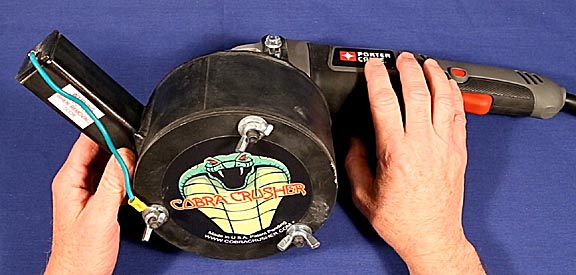

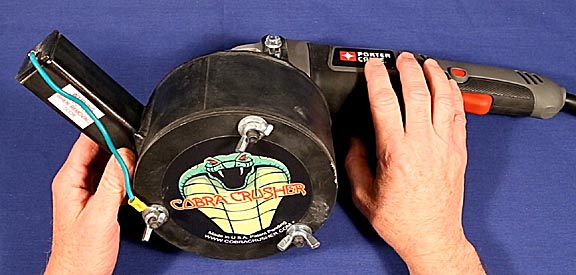

The Cobra Crusher gold prospecting rock crusher is designed to grind up sample rocks for panning to determine if they contain gold. Small, lightweight and easily powered by a rechargeable angle grinder, it's the perfect tool for remote hard rock gold mining. Although its 2016 price of $400 may give some people pause, it's an extremely durable, long-life, American made machine that guarantees years if not decades of reliable service.

There are several different configurations. One has a right angle bend to the feed tube. Others, like the one on this page, are straight. The face plates on older models have two holding wingnuts. Some have three and I've heard that one has four. A few have one-piece mounting arms that hold the angle grinder in place. Others have an extender arm that can be mounted on either the inside or outside of a short mounting arm. Exterior logos also vary considerably.

Regardless of the model. they are all powered by an angle grinder, which the purchaser must supply. The stated requirements are any plug-in unit rated at seven or more amps and any rechargeable unit of 18 or higher volts.

Assembly is straight forward: remove the Cobra Crusher's faceplate, remove the grinding guard and disk from the angle grinder and rotating the Cobra Crusher's hammers (the arm with the chain links) screw the Cobra Crusher's drive shaft into the angle grinder. It's not necessary to tighten it in place. The operating rotation naturally tightens it.

The Cobra Crusher grinds rocks up by hammering them with rapidly rotating heavy chain links.

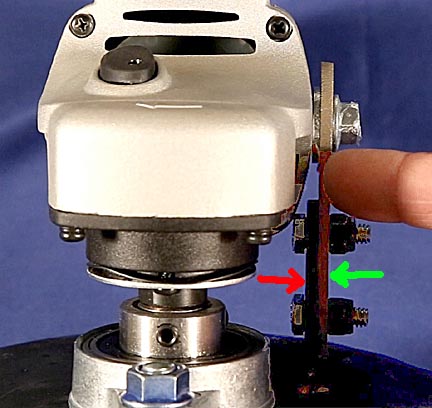

Cobra crushers with the moveable arm extension have a potential problem that could prematurely burn out the crusher's bearing. In the image below, the red arrow points to the fixed arm and the green arrow indicates the moveable extension that is bolted to the fixed arm.

If the extension is mounted on the inside of the fixed arm, the head of the upper bolt may prevent the angle grinder from rotating so that the angle grinder's face is parallel to the arm extension. If this is the case and the mounting bolt is simply tightened into the angle grinder to secure it, the angular difference in the two faces will result in torque being applied to the crusher's bearing. This can easily cause it to burn out long before it should. I've watched videos of Cobra crushers and their bearings start smoking after as little as 20 seconds. I suspect these have been forced together in a way the places torque on the crusher's bearing.

If the extension is mounted on the outside of the fixed arm, as it is in the images above, then the mounting face on the grinder and the surface of the extension arm will be parallel, though separated by about an eighth of an inch. Tightened down in this configuration, the bearing will once again be torqued. But, because the faces are parallel, all that's needed is a washer to fill the gap, as was done in the picture. Now the mounting bolt can be tightened down without placing any torque on the bearing. Each brand and model of angle grinder has a different body shape so only by trail and error will the best mounting configuration be determined. The important issue is to avoid putting any torque on the crusher's bearing.

I've run my Cobra crusher continuously for two minutes without the crusher's bearing over heating.

Once the

crusher is attached to the angle grinder and the faceplate is screwed

back in place the crusher is ready to go. All you have to do is feed

in some rocks.

I've seen them

fed into the tube all at once before the motor is started and one at

a time while it's running. The direction of rotation is away from the

direction of the feed tube so the chances of something getting

ejected is extremely small.

If feeding your crusher using the batch technique, I recommend adding no more than ten 1-inch diameter rocks. More than this and the crusher may jam and stall before it gets started. This isn't serious as long as the angle grinder's switch is released immediately. If this happens, shake the crusher a few times to break the jam loose and try again. I don't advise this because stalling the motor isn't good for the grinder, so keep the rock count down.

Feeding rocks in one at a time while the motor is running avoids the jamming problem, but even with all the safety factors designed into the Cobra crusher, I'm never comfortable doing so.

Youtube has many videos showing the Cobra Crusher grinding up a handful of rocks, like the ones on the left in the following image:

...into powdery-fine sand as shown on the right in as little as five seconds. It really does work that fast. Harder rocks like quartz seem to shatter the quickest. Softer, tougher material may take ten to twenty seconds, but it's still amazing how well it works. In fact it may work a little too good.

Rocks aren't just rocks. They are minerals. And some minerals contain dangerous compounds. The Cobra Crusher works so well it creates a lot of dust that's so fine it hangs in the air for as long as a minute. While it's not advisable to breath in any dust, it could be particularly hazardous it the rocks contained arsenic or other dangerous materials. I recommend wearing a breathing mask and/or working outside upwind of the crusher. Make sure no one is downwind. I admit that the chances of any danger is small, but do you want to take any risk at all with the health of your friends, wife, children or grandchildren?

I'd like to pass on the results of one experiment I conducted with the Cobra Crusher in case someone else wants to purchase one for the same reason. Doing so may save them a lot of money.

I review a lot of on-line gold paydirt sellers. The idea came to me that the +12-mesh and larger rocks that come with such samples might have some gold locked up in them. I used the Cobra Crusher to grind many samples up and found... nothing. Crushing the larger rocks into powder and panning it out didn't produce a single speck of additional gold. I was surprised at this but repeated the test so many times I came to the conclusion that the chances of finding extra gold this way was so small that I discontinued the practice.

So, that's my review of the Cobra Crusher. It's a great little rock crusher that work perfectly for grinding up small test samples. It's not designed for processing large amounts of material, but for a handful of rock at a time it's hard to beat.

Visitors

wishing to watch any of my 18 and growing collection of YouTube

videos about Backyard Gold Prospecting, please click on the following link:

Return to my main page to browse 60 other subjects