BILLIARDS! Dozens of articles on pool and billiard equipment

(Click here to browse 70 topics on my main site ranging from exotic kaleidoscope designs to the strange world of lucid dreaming.)

NINE

NEW ARTICLES!!!

1.

My new shaft by Dennis Dieckman has arrived! To read how it measures

up to the other shafts I've tested, click on: An

easy-to-build shaft tester and 11 cue shafts compared for straightness.

2. I've updated my pool room with a new table and more appropriate wall decorations. See My Pool Room for details.

3. Looking under the skirts of two tables. Comparing Olhausen to Brunswick construction.

4. Examining the accuracy of Brunswick's Centennial balls. Please click on Three types of billiard balls measured and compared

5. Why I trashed my Sardo rack! Please see: I take the Sardo Tight Rack for a test drive

6. A close look at Simonis 860 cloth A little history, close-up photographs, what happens over time to cause this cloth to slow down and how to restore it.

7. Cue ball wear See the bottom of the ball comparison article for what I discovered.

8. Click on Spot Touch-up Fix for the best way to pick up small bits of dirt off table cloth!

9. Pro 8-ball stats!

Please

scroll down to browse through all the articles or use the following

list of bookmarks to jump to a specific topic:

My

Pool Room

Spot

Touch-up Fix

Looking

under the skirts of two tables

Quantifying

table aging

What

Tune is Your Cue Playing?

My

Custom Cue

My

Meucci Nightmare

Read

this if you want to order a cue from Meucci Originals

Five

Meucci Blackdot Bullseye shafts tested for straightness

An

extreme cure for sweaty palms

A

Very Strange Cue Tip

Billiards

Newgroups

Shaft

Cleaning

Joseph

Picone Jump Tips

Get

to know your taper

A

comparison of APA and BCA 8-ball rules

Check

your pockets! NEW!!!

Pocket dimensions revisted

How

good is your wood?

Meucci's

Myth Destroyer

robot versus Predator's Iron

Willie

Links

to 89 cue makers

Deep

cleaning a pool table

Three

types of billiard balls measured and compared

Testing

a billiard ball cleaner

Two

quotable billiard quotes

An

easy-to-build shaft tester and 11 cue shafts compared for straightness

Experiements

in shaft straightening NEW!!! Shaft

straightening problem!!!

How

to measure your breaking speed

Four

chalks compared

To

drill or to stoke: comparing two chalking techniques

Learning

to jump

Billiards

after LASIK eye surgery

I

take the Sardo Tight Rack for a test drive

Electrify

your Sardo

NEW ARTICLE!!!

Four

cue tips compared Why Pool is the Hardest

Game in the World

The

Secret to Getting Better

Conquer

8-ball dread

Another

hint to help you shoot better

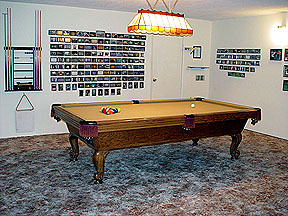

This room is a completely finished garage with windows, full-length drapes, wall-to-wall carpeting, and best of all my nine-foot Olhausen Provincial pool table. The room measures 20 feet by 17 feet so there's plenty of room to play without hitting the end of a cue on anything. I have the table recovered every three years with Simonis 860 cloth. It's great to have a quiet, dedicated room to work on the game. (Now... if I could just find more time to play!)

In case you were wondering, all of the small pictures on the walls, and there are many more out of sight, chronicle many of the engineering projects I've undertaken.

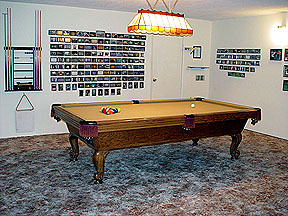

My New Pool Room!!!

After 19 years of use I decided to retire the old Olhausen, get a new table, and redecorate the room to reflect a more pool related theme.

But which table to get?

For several years I've wanted a table with the pockets cut exactly the same way as the tables used in nationally televised professional tournaments so I could see just how much harder they were to use. I also wanted the very best table I could get. The solutions to both problems were resolved by purchasing one of the Brunswick Gold Crown IV tables used in the WPBA San Diego 9-ball professional championship tournament held at the Viejas Casino. These tables are donated by Billiards and Barstools and then sold to the public. Officially the tables are used, but since each of the nine tables used only have a few hours of play they hardly deserve the adjective. Best of all, they aren't just as good as ones used in a professional tournament; they are the ones used. You can't get any closer than that.

With such a high-end table I needed to redo the room's decor. All the little pictures of my engineering projects came down, the room was repainted, and new photos of the top women and men hall-of-fame players with short biographies below them were put up. The effect is to make the room look larger and more completely a serious "pool" room. Here's how it turned out:

So, how does the Gold Crown IV play? Like a dream... and a nightmare

It's a dream because the table is rock solid. The Olhausen was steady, but if you bumped it hard enough it would creak a little, though not move enough to cause the balls to move. The Gold Crown IV? Bumping it is like running into a block of concrete. The rails are also great. Their extra-wide depth provides plenty of room for a solidly anchored bridge no matter how close the cue ball is to the rail. Even better, the curve cut into the rails, which extends through the sloped top of the cushions, perfectly matches the natural curve of a relaxed hand.

But... it's a nightmare because:

1. The extended rail depth cuts into the distance you can stretch and still reach a shot. I find myself having to grab the mechanical bridge about 10-percent more than on the old table.

2. The curve put into the top of the rails causes problems for shots where the cue ball is frozen to the rail. Take a look at the following image and you'll see the problem:

Because the nose of the cushion slopes downward, a level cue places the tip so high on the cue ball that a miscue is almost certain. To avoid this it's necessary to angle the cue and hit down on the cue ball, always a dangerous thing to do because it can cause masse' effects. This isn't a problem with typical designer tables like the Olhausen because the top of the cushion is flat and level with the top of the rail. On these tables hitting with a level cue strikes the cue ball perfectly. It's interesting to speculate why Brunswick designed the rails this way. I conjecture that professional players have enough control that they seldom leave the cue ball frozen to the rail so it's not an issue for them. In trade off the downward sloping cushion provides a more comfortable and secure bridge anchor.

3. The extra-large ball cups (capable of holding up to 10 balls each) are made of a soft, rubbery plastic and don't give off the same satisfying "thunk" of a traditional leather and wood pocket cup when a balls falls in them. It's a small thing but noticeable. After all, it's a sound we all love to hear. I'm thinking of placing a small, flat wood sound box on the bottom of each pocket to improve the table's acoustics. Another problem with these pocket cups is that they are so large and smooth that the first ball in rolls around for several second before coming to rest. This can be as distracting as an under-the-table ball return where you've got balls rattling around while you're trying to focus on the next shot.

4. Pocket openings on consumer tables average 5-inches wide for corner pockets and 5 and 1/2-inches for side pockets, at the large end of the BCA's sanctioned legal limits. This makes sense because table manufacturers want their customers to be happy and making pockets large so more people can make balls is one way to do this. For professional tournaments, pockets are smaller so the pros miss a ball once in a while making the matches more interesting. The pockets on the table I purchased from the Viejas WPBA pro tournament (held April 19, 2006) has corner pockets that are 4 and 5/8-inches wide and side pockets that are 5-inches wide. These tighter pockets make the game much more challenging. I'd estimate that they reduced my average run in 8-ball from 5 to 4 balls.

5. The sloped rails tend to make chalk cubes slide off and onto the floor.

6. The smooth Formica-like rail surfaces and nickel-plated pocket surrounds show up smudges and fingerprints much more noticeably that the real wood rails and leather pocket surrounds of the Olhausen.

Don't get me wrong. In spite of the previous few nit-pickss I love the table and look forward to enjoying it and the new room for many years to come.

From time to time a bit of lint, a flake of dandruff, or a small area of chalk mars the look of the table's bed cloth. The spot is too small for the hassle of brushing or vacuuming, yet you want a quick and safe way to pick it up. Using tape, sticky rollers, or even trying to scratch it up with a fingernail can raise the nap of the cloth in that area, potentially creating an uneven roll. What's needed is something that's tacky enough to just barely pick up the debris, yet not sticky enough to raise the cloth's nap. I found it.

Silly putty. It has the perfect amount of tackiness to pick up small bits of anything, including chalk, yet it won't pull up the nap. I've tested it by rolling it over the same small area of a piece of test cloth, virgin Simonis 860, 100 times and under a 10-power magnifier could not detect the slightest raising of the nap or the leaving of a residue. The trick is to remember to very lightly roll the silly putty over the area to be cleaned, never rub, drag, or press hard.

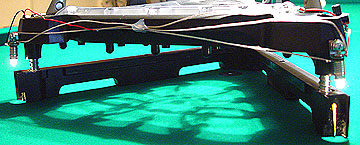

Looking

under the skirts of two pool tables

While waiting for the new Brunswick table to arrive, I got the idea that it might be interesting to see how differently it's constructed from a regular table. First up: let's take a look under the Olhausen to see how it's put together.

Looking along down the length of the underside of the table shows that the three slate sheets are supported by the outer box frame, made of 3/4-inch plywood, and two ribs placed under the slate joints. These ribs are 1-inch plywood. The entire box frame is stapled and glued together at the factory to form a single monolithic structure.

There is a strip of particle board between the slate and the top of the rib. Wedge-shaped shims are used to level the pieces of slate so that they create a smooth surface. Since only the area under the shims are in supportive contact with the slate and there are only nine shims visible, that means that there are only nine adjustment points on the bed. Worse still, as the shims dry out, expand, or overwise shift the slate can shift. This doesn't strike me as a very stable system. Yet, the table has worked perfectly for 19 years so it must be a better system than it looks.

The corners surprised me because they didn't have any additional bracing. After all, 1500 pounds of table is supported at these four points.

The underside of the rails show the bolts that attach the rails to the rest of the table. The bolts that hold the slate to the table screw through the slate and into the thick wood brace piece on the middle right of the picture above. here are four of these screws on each side of the table and two on each end. The side screws are far enough under the cushion that a ball can never reach it. But, the ones on the end rails are far enough out so that under certain conditions they could influence the ball's rebound.

Next: The Brunswick Gold Crown IV:

The Crown is built on site from eight sections bolted together.

This bothers me a little because as an engineer I know that bolts can loosen up over time. However, the bolts in the table are very large there are a lot of them.

The frame is made of 3-inch thick, built-up lumber, quite a bit beefier than the Olhausen's plywood.

Another interesting difference is that the Brunswick's slate is whitish-gray whereas the Olhausen's is very dark gray, almost black. Brunswick gets it's slate from Brazil, Olhausen from Italy. (Table experts will be debating forever the relative merits of Brazilian versus Italian slate. All I know is that they are both flat, heavy and hard. That's good enough for me.)

Because of it's essentially single-piece construction the Olhausen can be put up in two hours. The extensive on site construction required for the Brunswick resulted in its taking over 5 hours to assemble.

Instead of shims, the Brunswick uses 22 screw-type slate levelers. After assembly I examined these and found that less than half were used. Evidentially only the ones needed to level the slates are used and the rest left in the lowered position. I had expected them all to be raised to be in contact with the slate to provide the most even possible support.

This image of the bottom of the rail shows that the Brunswick has a more finished and solid look than the Olhausen.

The real question is whether or not the Brunswick is better than the Olhausen and if so, is it better enough to justify the price difference?

As an average player I have to confess that my game isn't good enough to tell the difference between the two tables. The Brunswick's rails are much more comfortable but the Olhausen looks better. The cushion action is so close that I don't see any difference in banking. The Brunswick's MSRP is $8500. The Olhausen's is around $4000. (I had to estimate this from comparing prices of several different Olhausen tables because they no longer make the Provincial.) Having a Brunswick competition table carries with it a certain value prestige-wise, especially as the one I got was used in a national professional tournament, but I'm not sure that's worth $4500.

NEW!!! A

close look at Simonis 860 cloth

A Little History:

The Simonis weaving mills were established in 1680 by William Simonis in Verviers, Belgium. This location was selected because the unusual calcium content of the local water made it the best possible for washing the wool. The company was a success from the start and focused on producing only the highest quality woolen fabrics. Simonis mills passed from generation to generation until 1790 when the then current owner, Iwan Simonis, renamed it after himself. To this day the mills still go by the name Iwan Simonis.

With the increased interest in billiard and pool tables over the last two centuries, the company decided to concentrate on producing only the highest quality cloth for these tables. They don't make any other cloths. This specialization has enabled the company to establish itself as the premier manufacturer of cue sports cloth. They currently advertise 14 different types:

Snooker cloths: 5000 (thickest), 7000 (thinner) 4000 (thinner yet but still heavier and thicker than standard 860 pool cloth.)

English Pool: 4000 (same as snooker 4000), 3000 and 2000 (Each progressively thinner and faster. The 3000 is about the same thickness as 860. But, all snooker and English pool cloths are 100-percent wool.)

Pool: 860 ( about 3/4-pound per square yard - the most popular pool cloth, specifically developed for 9-ball but the highest regarded all-around cloth), 760 (thinner and faster, 70-percent wool, 30-percent nylon) 725 (thin economy cloth.)

Carom: 300 Rapide (for 3-cushion billiards), 300 International (for serial carom games) 7219 Super Croise Champion (slower) and 585 (especially for cushions.)

Pyramid: 950 Rus Pro (same as 760, for Russian Pyramid Pool games) 930 Rus and 920 (progressively thinner versions of the 950.)

By far, the most popular cloth is Simonis 860: an all purpose cloth used in more professional tournaments than any other brand or type. Simonis 860 is a blend of 90-percent wool and 10-percent nylon. It's woven of worsted yarn ("worsted" means the yarn is made from the longest fibers and tightly twisted so that it resists fraying that could interfere with and slow down the ball as it rolls.)

Simonis 860

cloth. The weave is 40 threads

per inch by 30

threads per inch.

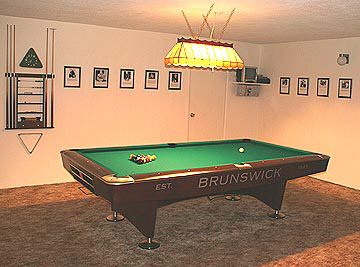

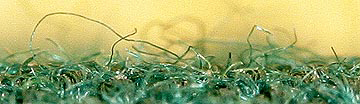

After weaving, the cloth is passed through a shaver that clips off any fuzz on the playing side of the cloth. This provides a hard, smooth surface for the ball to roll or slide on. The back side, which is unshaved, looks like this:

It's so fizzy that it's hard to make out the cloth's weave pattern.

Aging:

Playing on brand new Simonis, or any top-quality non-nap cloth, is an empowering experience. The surface is so smooth that long draws are easy and slow hits allow object balls to roll far enough to make it all the way to the pocket instead of stalling an inch short. This cloth speed increases the range of speeds over which the cue can be stroked, expanding play options. But, in time the table invariably slows down.

Two influences cause the cloth to slow down: abrasion of the cloth and chalk build up.

Every time the cloth is brushed the bristles of the brush drag across the cloth, pulling up some of the individual fibers twisted into the cloth's threads. In time this fuzzes up the surface.

An edge-up view of brand new Simonis 860 cloth.

The same cloth after 300 strokes with a brush, 2 year's worth of brushing.

As the ball rolls over the fuzzier cloth, it loses energy faster than a smooth cloth because it has to push more fuzz out of the way.

Even worse than brushing is using a sticky roller to pick up lint or dust off the table. Here's what new Simonis 860 looks like after just a few rolls:

Does this mean

tables shouldn't be brushed? No. Brushing is necessary to reduce the

build up of chalk, which doesn't reduce ball speed so much as it

kills sliding spin (English.) Here's a top-down view of a chalked

surface after it's been brushed off:

It's obvious that the color is lighter than the new cloth, indicating that there still remains chalk on the surface. Without brushing, which really just massages most of the chalk deeper into the choth where it can't interfere with the sliding of a cue, the surface chalk would build up to the point where shots using English would be very difficult.

This build-up of chalk and fuzziness is what slows a table down over time. What can be done?

Cloth

maintenance and restoration:

Note: I am not a cloth or table expert. I suggest the following only based on my experiences and am not recommending anyone else follow these procedures. I only know they have worked well for me over the last 20 years of taking care of my own table.

Since brushing pushes chalk into the fibers of the cloth, I reduce this by always vacuuming the table before brushing. This removes 90 percent of the chalk and greatly slows its build-up. I use a small head attachment without bristles that is glass smooth on the bottom so that it can't abrade the surface. I never us a vacuum with any sort of beater-bar.

Once or twice a year after vacuuming the table I gently dampen the bed cloth and use a wet-dry vacuum to suck up the water. This draws the chalk-ladened water out, deep-cleaning the cloth.

If the cloth is in otherwise good condition but it's obvious that it's frizzed up over time, I use a clean electric razor and shave the fuzz off. This sounds a little strange, and I admit it looks odd, but consider the following edge-up photos of heavily brushed cloth and the came cloth after shaving:

After a good wash and shave the cloth plays like new.

Is

this

much care worth it?

I've found that vacuuming before brushing easily doubles the length of time a table remains in good playing condition. One or two washes doubles it again and makes it look a lot better. Shaving is probably a waste of time because by the time the surface has been abraded enough by brushing to need it, wear spots under the rack's head ball and around the cue ball's break position will require the cloth to be replaced.

I watched the 2005 IPT 8-ball tournament with clip-board in hand to kept track of how often the top pros got balls in on the break. Combining this with the run-out statistics available on the IPT site provided some interesting statistics about how good the pros are.

First, the top 20 8-ball pros in the world get one or more balls in on the break 50-percent of the time.

Second, they break and run out an average of 14-percent of the time. (The top few players (Reyes, Bustamonte, etc) break and run out 25-percent of the time.

Combining these two statistics discloses that the top pros run out, if they get a ball in on the break, 50-percent of the time. The average of the top 20 pros is 25-percent.

What this tells me is that pro-level players (top 100-200 players on the circuit) only average one break and run out in every ten racks they break. This astounded me because I'd always assumed they almost always broke and run out and that it was rare for them to not do this. (Mind you, I'm not saying they aren't good or implying that I'm almost as good as them. I'm not even close.)

I posted these numbers so that serious amateurs who may not have access to tournaments in which to play can use them to rate their own play.

What

Tune is Your Cue Playing? NEW!!!

This seemed like a good idea in concept... oh well, you can't win them all.

Everything has a natural frequency at which it wants to vibrate. In the case of pool cues the frequency is audible and can be heard by lightly holding the cue hang vertically tip down with two fingers and tapping the cue. Let the butt slowly slip between your fingers until the vibrations are the loudest and you can hear its natural tone or pitch.

It's at its loudest when you're holding it at one of the minimum nodes of vibration. At this point, like the rest spots on a xylophone, your hand doesn't interfere with the vibrations traveling up and down the cue. Move your fingers further up or down from this point and the vibrations die out more quickly because your fingers are now located at a point where the cue is physically moving and your hand is dampening the vibrations.

My idea was that this might be one way to characterize a cue. Cues with high pitched tones might feel more lively than low-pitched cues... or perhaps the other way around. The problem is that while each of my cues has a slightly different pitch they are all so close that differentiation isn't possible, at least to my tin ears. My daughter thinks my playing Meucci sounds like it's resonating a D and the breaking Meucci a G.

Still, it's an

interesting exercise.

The only cues I've used for the last fifteen years were the one-piece Dufferins that came with my table. Then for Christmas of 2002, my bother in law, with whom I've shared many a hard fought battle over the last 30 years, gave me a better quality two-piece Dufferin. This cue helped me play better and made the game more fun. Because of this experience, in 2003 I decided to get highest quality cue I could find.

My only criteria was performance. I wanted a cue from a manufacturer that could prove that his cues were better than any other. With this in mind I began searching the Internet for cue performance comparisons... and found absolutely nothing (with one exception.) Every manufacturer, except one, at most made some vague statement that his cues were the best but provided no empirical proof to back up this claim. Cuetec and Predator offered explanations why they thought theirs were the best, but neither offered quantitative testing to substantiate these claims. The vast majority of manufacturers focused their sales efforts on showing off the attractiveness of their cues. A good looking cue is nice but I'd rather have one that'll help me win games. (I don't want a work of art... I want a weapon.)

Out of the 145 manufacturer sites I found, only one provided both lengthy explanations about the engineering reasons why his cues were made the way they were and quantitative, repeatable, verifiable experiments that validated his claim that they are the best performing cues in the world: Meucci. The shear mass of scientific information available on the Meucci site is far too great to repeat here. I urge visitors to use the link at the top of the cue maker link list below and see for themselves. What I came away with from the Meucci site was that Bob Meucci approached designing and developing his cues as an engineer would: define what cue performance means and figure out how it can be quantified; develop a cue to maximize this performance; thoroughly test it to verify that the cue performs as it's supposed to, and most importantly present this information to the public for peer review. Meucci is the only company to do have done this and for that it earned my respect... and my money.

(Annie O's site also has numerical data on cue performance but all of it comes from Meucci research.)

Comments

about reputation and endorsements:

When I started thinking about getting a good cue the first name that popped into my mind was Balabushka. Then I realized that the only reason this happened was that I remembered hearing that name in the movie The Color of Money. At the time I didn't know anyone who had owned one and had compared it to other top line cues to determine if it was better than them. Reputations are often like this. We hear something from somewhere and for some reason it sticks and we think that it must be a good product. Perhaps it is. But word of mouth isn't acceptable as fact in scientific circles and isn't good enough for me. I may have heard somewhere that such-and-such is a great cue but I want more. I need the manufacturer to prove it with hard numbers. Meucci was the only company that does so.

(Interesting point: The writeup on the Joss website claims that while the cue in The Color of Money was said to be a Balabushka, it was really a Joss.)

Another problem with purchasing anything based on it's reputation is that a good reputation can persist long after quality declines.

I completely ignored professional endorsements when selecting my cue for two reasons. First, I doubt the objectivity of any endorser who's being paid thousands of dollars to say the product they endorse is better than another. Does the fact that Allison Fisher endorses Cuetec mean that Cuetec is better than Viking or Predator? I honestly think that if Viking offered her twice the endorsement fees as Cuetec she'd switch the moment her contract with Cuetec was up. Second, I do not believe that the cues endorsing professionals use are the cues the public can purchase. It's a safe assumption that out of a production run of hundreds of shafts the manufacturer sets aside the few that are the cream of the crop to save for their endorsing pros, then has them custom tapered to the pro's specifications.

The cue I ordered:

After weighing all of the above, I decided Meucci was the way to go and ordered a custom cue which started out as a MTC-4 with a power piston butt and Blackdot Bullseye shaft. (Click on Meucci and scroll down 2/3 of the page to see what a stock MTC-4 looks like.) To satisfy my particular (some might say peculiar) aesthetic preferences, I had the butt modified as follows: the white linen wrap was changed to black, the chrome joint collar and butt cap were replaced with black units, the point and butt sleeve designs were replaced so that the butt was solid black from cap to joint, and the ring designs from a Meucci FR-1 cue were added to the top and bottom of the butt and to the bottom of the shaft. The cue weighs 18 ounces and has a 12.5 mm ferrule. I requested that the linen wrap be polyurethane coated because I found that after a few months of play linen absorbs enough sweat and oil from the hand to make it feel sticky, hindering a smooth stroke. Washing the linen doesn't get all of the oil and chalk stains out and runs the risk of having the moisture warp the butt.

The cue was ordered on 13 October, 2003 and was delivered on 10 February, 2004.

How the cue was packed:

The cue was shipped in a single strength triangular cardboard box. Inside, it was bagged in a plastic sleeve and wrapped in single strength corrugated paper.

The cue: A plain but deadly weapon. (Black is the hardest of all colors to get a perfect surface. Nothing else shows up defects as much. The entire butt was perfect without a single scratch, bubble, or defect of any kind. The finish was like glass. The inlays were razor sharp and tight and smooth.)

![]()

The

tip: (Meucci uses a medium-hard, modified, Le Professional tip from

Tweeten Fibre. Bob Meucci was used as a consultant in the development

of this tip in 1969 while employed by National Tournament Cues in

Chicago, IL. I asked how the LePro was modified and was told that it

is radially compressed to increase the density on the sides.)

![]()

Ferrule:

(Meucci uses a soft, flexible ferrule that resists cracking,

splitting, chalk, and is designed to minimize cue ball deflection. It

is more translucent than most ferrules and has a slightly lower ring

when tapped. Both these characteristics reflect the softer nature of

the material used in it's construction. Meucci specifically designed

the ferrule to reduce cue ball deflection. The ferrule is 1 and 1/4

inches long.)

![]()

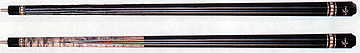

A

closeup of the 35 layer Black Dot Bullseye shaft: (The Northern Hard

Rock Maple veneers used are so thin and the 200 pound per square inch

laminating force so great that unlike other built-up shafts, those

made by Meucci have the adhesive driven into every pore in the wood,

saturating it to the point where the glue and wood form a single

monolithic structure. There are no zones where there is only wood or

only glue.) Actually, the lamination rate is 35 layers per inch.

The number of laminations in any particular shaft depends on the

diameter of the shaft at the joint. The picture below is at ten-times

magnification. In actual viewing the layers are so small as to be

almost invisible. Careful inspection shows that the laminations

appear to be laid down with the direction of the grain reversed at

each layer to maximize the homogeneity of the shaft.

This shaft tested out with only a 0.002 warp, which is outstanding.

Joint: (Meucci uses a 5/16 by 18 tpi union.)

open

closed

The butt end and cushion: The details of the design are razor sharp. The apparent softness of them in this picture is the result of reducing the image to 72 dpi for the Internet. (The design may seem plain to most players, but because I prefer understatement it suits me perfectly. Also, I could have paid $2,000 more for a fancier design but it won't play any better.)

My cue case:

A

closeup of the case's logo:

How

does the Meucci feel?

Compared to my old one-piece and two-piece Dufferins, the Meucci feels very slightly heavier in the butt, which I find more comfortable. The Blackdot Bullseye shaft is extremely slick and slides through a bridge without the slightest drag. The biggest difference is that unlike the Dufferins, the Meucci has a much longer pro taper so the shaft doesn't choke in the bridge at the end of the stroke. The Meucci modified Le Pro tip feels hard, almost brittle. But it holds chalk well and doesn't miscue so I don't intend changing it. (Though I have to admit I miss the mellow feel of a Triangle tip.) The only negative observation I have about the cue concerns the coated linen wrap.

I have very dry hands and can shoot for hours with a cue with uncoated linen without having to wipe perspiration off them or use talc. Yet I find that the polyurethane coating plays very warm and causes my right hand to sweat a little. It's not a big problem for me but for people with a sweaty-hand problem this could become a nightmare.

I had expected to go through a period of adjustment with the Meucci, especially considering all I'd read about how flexible Meucci shafts are. This turned out not to be the case. I was able to play better with it the first time I tried it. Although the balance was slightly further back, it felt fine and this was such a minor point that I doubt I would have noticed it without switching back and forth several times between the Meucci and the two-piece Dufferin. I did notice that the first time I played with the Meucci I completely missed the object ball on several very thin cuts. I couldn't understand this at first but later it occurred to me that these misses were probably the result of the reduced squirt the Meucci exhibits. This is a miner issue that I'll adjust to after playing with the cue a while. All together, I'd say the Meucci improved my game starting with the very first stroke. Holding a cue of this quality makes me feel better and play with more confidence. Even if it only improves my game fractionally, it makes the game more fun and in the end that's what it's all about. In time, and with diligent practice, I hope to become a good enough player to be worthy of this cue. Until then I'll simply enjoy it for the great weapon it is.

I also ordered and all-black cue with a power piston butt and a black dot bullseye shaft to use as a break cue. Like the playing cue, it's finish is perfect. The shaft had a 0.009 inch warp, which is at the low end of excellent.

I've read many posts on various billiards newsgroups claiming that the quality of Meucci cues has been very poor for many years. The most common problems relate to shafts warping over time, inlays coming loose and extremely long repair times for returned products. The problem with such claims is that the only people who report them are those who have received defective cues. People who never have any problems are much less likely to mention it. For myself, I intend to monitor my own cues closely to see if I have any such problems. If I do, I will be sure to report them here.

I understand that after an absence of a few years Mr. Bob Meucci has retaken control of his company and is trying to improve the quality of his products. I sincerely hope this is so and that he was successful before the order for my cues was filled.

Important warning! If you are thinking about ordering a cue from Meucci Originals, please be sure to read the following two articles regarding my order.

(You won't believe this horror story but it's true.)

While I have nothing but praise for the cues Meucci made for me, in fairness to anyone reading the account above and considering ordering a Meucci cue based on my experience I have to state that all did not go smoothly with the order. It was, in fact, a nightmare.

When I placed my order I was careful to have the sales representative (Mark) read back my description of what I wanted: an 18 ounce FR-1 with a Blackdot Bullseye shaft, a Power Piston butt and solid black shoulders (no points). I also ordered an 18 ounce solid black breaker with a Power Piston butt and Blackdot Bullseye shaft. He told me that these cues would be easy to manufacture and should be done in three to four weeks. He then took my credit card number and I made sure to have him read it back to me to make sure he had it correct.

After three weeks I called to see how things were going. This time I was told the cues would take six weeks. The breaker might be a little earlier.

A week later I called again and was told the breaker was shipped on 28 October. When I asked for a UPS tracking number the lady I was speaking to said she couldn't find it. She said she'd locate it and call me back. She never did. I called the next day to inquire about the tracking number and was told the person was out, please call back the next day. I did and she still wasn't available, I had to try again tomorrow. I did and this time was told she simply couldn't find the tracking number. I waited another week and when the breaker hadn't arrived I called and was told it hadn't been shipped on October 28 after all but on November 4th instead. She had no explanation for the confusion.

I observed something in the second and third calls that began to make me feel uneasy about the order. The receptionist answering the phone sounded lethargic to the point of being half asleep. Additionally, she often spoke with such a lazy drawl that she was difficult to understand. This did not instill in me the sense of confidence and pride that I would expect from a prestigious company like Meucci. My concern was that if the person charged with giving customers the most-important first impression of Meucci Originals didn't care enough to put forward a positive impression, then other employees working out of sight of the public, like those in production and shipping, might be even more apathetic. As I was shortly to discover, events transpired indicating that this was the case.

I received a call shortly after this telling me the credit card number I'd given was invalid and that the solid black break cue hadn't been shipped after all. After having the woman who called read the card number back to me I discovered that they had dropped one digit from the number and hadn't noticed that the card number was one digit short. This surprised me because as stated earlier when I placed the order I made sure to have the sales representative read the card number back to me, and he had it correct. This problem was quickly resolved... or so I thought, but more on that later.

The all-black breaker arrived on 11 November... in a box with eight inches of one end crushed and all but broken off by UPS's not-so-gentle handling.

As I opened it I discovered packing was extremely light, too light in my opinion for a valuable cue. There was only a single-strength outer cardboard box and a single wrapping of one-sided corrugated paper inside. Also, there were no "Fragile" or "Handle with Caution" labels on the box. This made me think that if Meucci valued their cues so little as to provide minimal protection then they also might have a similarly low value for their production standards. Also, the joint pin was not protected in any way. In fact there was a small hole in the end of the box the same size as the pin indicating that it had been dropped and the pin had perforated the box. Fortunately, the pin and joint appeared unharmed.

The damage to the box resulted in a scratch to the butt so I decided to avail myself of Meucci's return policy. I called and was told they would send me a UPS tag for free return. Before repacking the breaker I assembled the cue and rolled it on my table. I was shocked to see a large wobble. I took the cue apart and rolled the butt, it was straight. I rolled the shaft and it wobbled. On my shaft tester I measured a warp of 0.022 inches. This is worse than all of the 16 year old one-piece Dufferins I got free with my table. The warp was gradual and smooth along the full length of the shaft, indicating it occurred during production and was not the result of being damaged in shipment. I called the person I placed the order with and let him know I was greatly disappointed. He directed me to return the breaker with a letter detailing all of the problems with the cue.

On 24 November, six weeks after placing my order and when I had been told the playing cue should be done, I called Meucci to get a status on it. At first I was told they hadn't even started on the playing cue. When I commented that I had been told it would be done six weeks after placing the order I got put on hold for several minutes and was then told it was somewhere "on the floor" being made. The person I was talking to could not give an estimated completion date.

I called on December 15th about the playing cue and was told it still wasn't done and wouldn't be shipped until the 22nd.

The cue still hadn't arrived by December 30th so I called again. The first lady I talked to couldn't find any information on the order. She transferred me to a man who said the order had been completed but not shipped. He didn't know why. After being transferred to a third person I was informed the shipment was on hold because my credit card number was invalid. (Remember the problem with this I mentioned earlier? That's right, Meucci still hadn't corrected their records, the missing digit had not been added as I had asked them to earlier.) I explained the correction a second time and was told the cue would be shipped today.

While I had them on the line I asked to speak to the repair department about the all-black cue I'd returned. The man I was transferred to said it had been sent "to the floor" for repair and even though they had had it for five weeks, he couldn't tell me when it would be finished and shipped. He did promise that the warped shaft would be replaced.

On January 7th things really got bad... the playing cue arrived. The box was uninjured so I foolishly thought things were finally starting to go my way. Was I wrong. I opened the invoice and my heart dropped to my gut. I'd ordered a FR-1 with a power piston butt and a solid black forearm, no points. The invoice only said FR-1 with solid black forearm. I'd paid extra for the power piston butt and didn't get it. When I opened the box I got a second shock: they hadn't even sent the cue on the invoice! The cue in the box was a pure FR-1 with points; no power piston butt and no solid black forearm.

The cue on top is what I ordered and at least looked like the cue described on the invoice. The cue on the bottom is what I got. I can't understand how anyone could fail to see the difference.

The bottom line is that Meucci charged extra money and didn't deliver on either of the two modifications I paid for. Also, the people packing the order failed to notice that the cue they shipped wasn't the cue on the invoice.

I called Meucci Originals the next day and after getting shuffled around several people I ended up talking to Deron in the Repair Department. He had no idea why I had been transferred to him but was willing to help resolve the problem. He talked to the people in the Production Department and discovered... (Are you ready for this?) ... that the cue I ordered and paid for and had waited three months for HAD NEVER BEEN BUILT! I explained that when I placed the order with Mark in Sales I had him read back what he had written on the order to make sure he'd gotten it correct. He had. Deron apologized for the confusion and told me that he would speak to the people in Production and have them start work on the cue today (January 8, 2004) and he would personally expedite it. He also said that instead of starting with a FR-1 they would start with an MTC-4 and make the butt solid black. That way I'd be certain to get the power piston butt I wanted. Deron also promised me that the replacement cue should be done much quicker than the first one. He explained that once they received the returned FR-1 from me they would credit my credit card and then would rebill me once the new cue was sent to me.

I was reluctant to return the FR-1 because it had the straightest shaft I'd ever tested up to that time. I asked Deron if I could arrange to have it put on the new cue and he said that all I had to do was request it in the letter returned with the FR-1 explaining why I was returning the cue. I did this and went a step further. I attached a separate tag to the shaft itself and wrote on the tag my request to have it put on my new cue. As it turned out this was a waste of time. My request was ignored and I wasn't even given the courtesy of an explanation why. I'd hoped the company would have granted my request in consideration of everything I'd been put through on this order. In this Meucci once again disappointed me.

During the last call to Deron, someone named Karen told me a UPS call tag would be sent to return the stock FR-1. These usually take two days to arrive. When, after a week, it still hadn't gotten here I called and talked to Gail Wicker who told me it had never been sent. She promised to do so immediately.

The tag arrived three days later.

Three weeks after Deron had said that the cue would be started, I called him to get a status on both cues (They'd had the returned breaker for nine weeks by this time.) He said he remembered me and had given the follow up letter about our conversation I'd sent him to the production manager. Deron said everyone was clear about exactly what the playing cue was supposed to be. He also said he had no idea about the status of the cue and that the plant manager wasn't in the building so he couldn't ask him about it. Deron read my telephone number back to me off the order paperwork, which gave me the impression that he was going to find out that afternoon what was going on and call me back. He never did.

I called a week later on 2 February. Deron was out so I asked to speak to anyone who could help me find out the status of my cues. The receptionist, who once again sounded more asleep than awake, put me on hold. After a few minutes someone picked up the phone and asked for my name. I gave it and she said the records indicated that the solid black cue was still "on the line" being made and that it should be shipped by the end of the week. This statement concerned me because I'd heard similar statements like, "it's in production and should ship in a week," so often I've become to think it's a stock stall used anytime a customer calls and no one really knows what's going on.

Then I made a mistake... I asked about the playing cue. The response? "I'm sorry sir, I can't find any record of it. What type of cue was it?"

I counted to ten and as calmly as possible said I'd call back later when Deron was in.

I called again on 3 February and this time Deron was available. He said that the playing cue was getting its final finishing coat today and should be in the mail to me by 6 February. He said he didn't know what the status of the all-black cue was.

The playing cue finally arrived on 10 February... in a box half-crushed with tire marks all over it.

Someone at UPS had driven over it. Worse still, since it was delivered while I was out it had been left leaning against my front door in full view of anyone who wanted to walk away with it. I'd think Meucci would direct UPS to only deliver if they could get a signature to make sure it got into the owner's hands.

Fortunately, the cue survived unharmed. It plays great but I have to admit that the nightmare of getting it has been so bad that I cringe a little every time I go to play with it.

But, I was about to learn that the nightmare was far from over.

Remember when Deron explained that when they received the FR-1 sent to me by mistake they would credit my credit card account and rebill me once the new cue was sent out? They never did. Instead they kept the money for the FR-1 and sent an invoice with the new cue with a zero cost. This actually made things simpler. But, the fact that they didn't do it the way they said they were going to do it was one more example that the people at Meucci either don't know how transactions are handled or arbitrarily change them without informing their customers.

I called on 19 February to get a status on the all-black breaker cue. Again, the receptionist sounded asleep and apathetic. (FYI, all my calls were placed at 11 am in the Meucci time zone so it wasn't like I was calling first thing in the morning.) I asked to be transferred to Deron in Repair, got connected to Karen instead, who finally got me transferred to Deron. He explained that he had checked on the status of the all-black cue three days earlier and could find no record of it and was afraid that it had, "fallen through the cracks." I explained that I had already been waiting three months since it had been returned (four and a half months from when it had first been ordered) and admitted to getting a little impatient about getting it. He promised to talk to the production manager when he got in.

I called again on 20 February and after being put on hold three times for a total ten minutes, was informed that the all-black cue was complete and would be shipped on 23 February. Deron promised to inspect it himself before packing and use a larger, heavier shipping box for added protection. I appreciated this but it made me wonder why, since they have heavier shipping boxes, they don't use them to protect all their cues? This question is significant because someone I talked to at Meucci mentioned that cues damaged in shipping were a chronic problem. Doesn't it make sense to invest an extra dollar or two on padding and shipping to make sure cues arrive undamaged and don't have to be returned? Meucci Originals could even offer an extra-heavy-packing option to customers that the customer could pay for. I know I'd certainly have availed myself of such a service.

I called on 25 February to see if the cue had been shipped on the 23rd as promised. It hadn't. The receptionist told me that it had been shipped one day late, on the 24th. When I asked for a UPS tracking number, she put me on hold for five minutes. When she came back she said the cue hadn't been shipped on the 24th after all as she had originally said. Instead, she said they hoped to get it out today, on the 25th.

I called on February 27 to find out if the cue had been shipped. I was put on hold for six minutes then someone hung up on me. I called back and this time was put on hold for only three minutes before someone came back on the line. They told me the cue had been shipped as promised and I was given a UPS tracking number.

The breaker finally arrived on 2 March, 2004... and the nightmare started all over again. I'd ordered an 18 ounce solid black cue. (The damaged one I'd received back in November was solid black as promised.) When I opened the box I discovered the cue they'd sent me had ugly off-white plastic collars near the joint and the bumper. Making matters worse, the cue was a 19 ounce, not the 18 I'd ordered. The shaft had an unacceptable 0.014 inch warp and the amount of wobble at the joint when the cue was rolled across my table suggested that there was something wrong with the joint. Finally, Deron had promised that this cue would be shipped in a heavier box in consideration of the two previous crushed boxes. It hadn't. The box it was in was the same as all the others.

That was the last straw. I was too tired to fight any more. I called Deron and asked him to send me a UPS tag so I could return the wrong and defective cue I'd just received and get a refund.

And that was that... or so I thought.

On 5 March I got a call from Deron. He said that he had been so concerned about the mix-up over what was supposed to have been a top-grade all-black cue that he'd spent several days tracking down the problem. He explained that the day my cue was shipped was one of those days where everything goes wrong. While he was busy at the plant with two dealers, one of the people working with him called to say that there were two cues marked for Wayne Schmidt and wanted to know which one to send. He told them to send the best one, which I assume the person interpreted as the one with the most decoration, i.e. the white collars. (At this point I was wondering why there were two cues with my name on it, especially when one of them wasn't the cue I'd ordered.) The cue that person sent turned out not to be the one Deron had intended for me. He further explained that he'd secured the all-black cue that was supposed to be sent and had personally checked it to make sure it was what I had ordered and that the shaft was straight. He offered that if I got this cue and wasn't at all satisfied with it I could tell him so and he would credit my credit card account for a full refund and I could keep the cue for free.

As tempting as this offer sounded, I was so disappointed with my Meucci experience that I said, "Thank you, but no thank you." I simply didn't want to suffer through another round of endless waiting only to get the wrong cue, one damaged in shipping, or one with a warped shaft. Deron emphasized that the cue was absolutely perfect and was one he felt I really should see. In the end I acquiesced and accepted his offer. He mentioned sending it out two-day express so I should have it by 8 or 9 March.

I should have known better... the cue never came. I called Deron on 15 March and asked for the UPS tracking number so I could find out where it was. He'd never sent it. He was very apologetic and promised to get it in the mail immediately via UPS Air so I would have it in two days.

I'm happy to say that it arrived two days later in a much heavier box. The cue was in good condition and the shaft had a warp of 0.009 inches, which is very good.

Finally, thankfully, I can now consider my Meucci nightmare over.

Nit Picking

Added to all of the above was the irritation of repeatedly being placed on hold for over five minutes. In as much as these were long distance calls during the high rate period this did nothing to endear Meucci's customer relations to me. In total I paid 60 dollars in long distance calls to get the mess with Meucci resolved.

Additionally, each time I spoke to someone regarding the playing cue I'd ask what they had on the order form. Every time they said it was a FR-1. I stopped them each time and explained that that was not what I had ordered and preceded to re-describe the cue I wanted. This happened a dozen times yet in spite of all the times I corrected the person reading the order to me none of them ever changed the order form. This suggests that they weren't really listening to their customer. They had something on paper and no matter what the customer said they were going to follow what was written down.

Over half of the time the person answering the phone sounded apathetic or half-asleep and had such poor enunciation that several times I had to have her repeat what she said so I could understand it. This weakened the company's credibility. The receptionist's voice provides customers with their first impression of Meucci Originals. Since first impressions are always the most important, it would be helpful to have someone who reflected a positive attitude and had a clear voice that is easy to understand.

One final complaint is that in June of 2003, November of 2003 and early February of 2004 I called Mark in Sales and requested a copy of the videotape of the Myth Destroyer in operation. Each time I was told it would be in the mail shortly. It's now late March, 2004 and I still don't have one.

All the delays and poor customer relations soured my entire Meucci experience. Had they told me from the start that the playing cue would take four or more months I wouldn't have minded so much, but their repeatedly changing the completion date gave me the impression that they didn't have enough grasp of their own production schedule to know when they were going to complete a given cue. If they can't be sure about a simple matter like this, how can I be sure they are any more competent when it comes to the much more complicated task of making a cue?

As my positive articles on the Meucci Originals website and the quality of the playing cue I eventually received prove, I am a staunch advocate for Meucci cues. Yet my experiences in dealing with Meucci Originals was horrendous enough to completely alienate a pro-Meucci supporter like myself. I will never ever order another cue from Meucci Originals.

Bob

Meucci's Response:

On the same day I received the second all-black cue and arranged for it to be returned for a refund, I sent Mr. Bob Meucci the following letter expressing my gratitude for the outstanding playing cue his company made for me and the problem I had obtaining it:

Mr. Bob Meucci, President

Meucci Originals, Inc.

#1 Meucci Center Drive

Sledge, MS 38670

Re: Letter of Appreciation and Concern

Dear Mr. Meucci,

I wanted to thank you and everyone at Meucci Originals for the outstanding cue they made for me. Right out of the box, this cue enabled me to shoot better than I'd been able to with many other brands.

One of the pages on a website I maintain is dedicated to billiards. I've added two articles about your company in recognition of Meucci Originals outstanding work. The first is an evaluation of the excellent technical content on your website and a link from my site to it, which I've posted in the number one position of a link list to 145 online cue makers I've assembled. I've also posted an article on the great cue you made for me. Hard copies of both articles are attached to this letter as a courtesy. If you have any changes or additions you'd like, please let me know what they are and I will be happy to accommodate your wishes.

While I have nothing but praise for Meucci cues, I regret to say that I have serious concerns about the many ordering problems and production errors that occurred during the processing of my order. I appreciate that a large company that's geared towards manufacturing twenty thousand cues a year can't always accommodate individual small orders in an efficient manner. However, in my particular case my experience ordering from and dealing with Meucci Originals was nothing sort of a nightmare. Attachment 3 chronicles everything that went wrong with the order. I'm not sending it as a complaint, but as feedback so that you might see what dealing with Meucci Originals looks like from one customer's perspective. I have attached a self addressed and stamped envelope to this letter and would be very interested in your comments about my experience.

I greatly appreciate your taking the time to read this letter and once again, thank you very much for making my cue. I will value it for a lifetime and will be proud to show it off where ever I play.

Sincerely and with deepest respect,

Wayne Schmidt...................................4

Attch:

...........................................................1.

Copy of the Meucci website link

...........................................................2.

Copy of the Meucci cue article

...........................................................3.

Meucci order problems

...........................................................4.

Response envelope

The letterhead on the cover letter had my address and telephone number on it. The letter and attachments were sent certified mail on March 2, 2004, with a return acknowledgement so I'd be informed by the post office when it was received and by whom. Melanie Gregory signed for the package on March 8, 2004.

As of February 1, 2005 I have not heard from Mr. Meucci or anyone else at Meucci Originals in response to this letter. I can only assume from this that he, or his representative, doesn't care enough about his customers to send even a simple form letter of apology.

I did receive, finally, a copy of the Myth Destroyer robotic cue testing machine on 24 March. It came with no note or communication of any kind.

I want to make it absolutely clear that these are only my experiences and are far too limited to use as an indicator of Meucci's overall quality and customer service. Meucci provides thousands of great cues to satisfied customers every year. If it didn't, Meucci wouldn't still be in business. It is not my intent to dissuade anyone from purchasing a Meucci cue.

NEW!!! Please read this if you want to order a cue from Meucci Originals

If, after reading the article above about My Meucci Nightmare you still wish to order a cue from Meucci Originals, I highly recommend you do the following to help make sure you get the cue you ordered:

1. When you call in your order be sure to have the person taking the order read it back to you and confirm that what he says is exactly what was written down on the order form. (Note: Meucci shafts come in 13 and 14 mm diameters. Be sure to specify which you want.) Also ask for the cue's completion date. Get the salesman's name and business address. Ask that the cue be shipped in the heaviest box available, that the box be labeled "Fragile," and that someone has to sign for it when it's delivered. (If these extra shipping requests cost extra, consider paying it. It could worth it, especially if you're order a cue or cues worth thousands of dollars.)

2. Write a letter to the salesman that reiterates everything that was agreed upon when you called in your order and mail it to him. Include a self address and stamped envelope and request that he use it to send you confirmation that everything in the letter is what's recorded on the order form. If you are ordering a custom or modified cue, send a drawing or picture of what you want with the letter. (One way to make a good picture of a cue that doesn't exist is to take a picture from the Meucci site of a cue that's similar to what you want and use a graphics program like Adobe Photoshop to modify it to look like the cue you want.)

3. Send a copy of the above letter to the Plant Manager (Mr. Randy Wicker as of Spring, 2004) and again ask him to use the enclosed self addressed and stamped envelope to let you know that he's received your order, understands what you want, and verifies the completion date.

5. Cross your fingers, don't break any mirrors, start going to church and hopefully you'll do better than me.

Good luck!

NEW!!! Five Meucci Blackdot Bulleye shafts tested for straightness

During the process of getting the two cues I ordered from Meucci Originals, I had the opportunity to test five 35 layer per inch laminated Blackdot Bullseye shafts. Two were outstanding with warps of only 0.002 and 0.004 inches. One was excellent with a 0.009 inch warp. The fourth shaft had a very noticeable warp of 0.014 inches and the fifth a grossly unacceptable warp of 0.022 inches. Both of these last cues exhibited an obvious wobble as they were rolled across a pool table.

(Note: I conducted a survey of several custom and production cue manufactures and they told me that custom builders strive to keep the shaft warp to 0.005 inches or less. Production companies work to keep it below 0.010. From my own experiences testing 20 shafts from half a dozen manufactures I've come to believe that 0.000-0.005 inches of warp is outstanding, 0.006-0.010 is excellent and 0.011-0.013 is tolerable. These assessments are based on the rarity of truly straight shafts. At around 0.014 inches of warp you can begin to see the cue wobble when it's rolled across a pool table. I consider this unacceptable because even if it were proven that such a warp does not effect shooting accuracy it looks so bad it makes the cue's owner look foolish.)

A

sample space of five shafts out of the many thousands Meucci

produces every year is far too small to be significant. However, the

badly warped shafts shows that Meucci's quality control system can

let bad shafts slip through. Fortunately, Meucci has a

no-questions-asked

return policy.

I asked a representative how Meucci tests their shafts prior to shipment. He stated that the company has a flat, glass-topped table on which the shafts are rolled as the tester observes light passing through the gap between the table and the shaft. My own experience with this system indicates that it can detect warps as small as 0.004 inches. How the two shafts I got that had warps over three and five times as great got through is a mystery.

One curiousity about the shafts with the 0.002 and 0.009 inch warps is that when I tested them for roundness they turned out to be slightly oval. The 0.002 inch shaft was 0.005 inches greater in diameter parallel to the lamination layers than it was perpendicular to them. The 0.009 inch shaft was 0.002 inches greater in diameter parrallel to the layers than perpendicular to them.

One explanation for this is that as the shafts are turned on a lathe, the friction of cutting heats them up and causes the wood to expand. If the expansion rate is greater perpendicular to the laminations, then that diameter will expand more that the diameter parallel to them. Assumeing that the shaft, while warm, is turned perfectly round, then as it cools the diameter with the greater expansion will shrink more than the other, creating an out of round shaft.

Since these differences are so small and symmetric I doubt, though I confess I don't have any way to confirm it, that these out-of-roundnesses will not significantly effect play.

What this very limited sampling suggests is that Meucci Originals can make very straight shafts. They can also pass very warped ones. If I ever purchase another Meucci cue I will be sure the test it carefully before paying for it.

Six

Month Shaft Update: I've received

three emails from people claiming that they had purchased Meucci

Black Dot Bullseye shafts and that they had warped after several

months. Because of this I decided to see if this happened to my two shafts.

Six months after I got them, I tested both shafts again. The playing shaft (13 mm with an outstanding 0.002 initial warp) now had an unacceptable 0.017 inch warp. This is enough to plainly see wobble as it's rolled over a table. The shaft from the breaker cue (14 mm with a very good 0.009 initial warp) was exactly the same as it was when I got it.

Meucci shafts come with a one year warranty but I am not going to return it. After enduring all the harrowing experiences of dealing with Meucci to get the cues, I have no taste for working with them again. Instead, I'm using the cue to develop a new cue straightening technique.

The bottom line is that if you purchase a Meucci, make sure you have the guaranty in writing and that you keep the receipt... you may be needed both in the future.

Have a question about billiards? Want to chat with fellow pool players? Try one of the following newsgroups:

Each of these forums has its own look and atmosphere. Some of these links take you to a listing of several billiards groups, such as Equipment, Instruction, Rules, Chat and so on, to make it easier to select a group that most specifically caters to individual player's interests.

In February,

2004, I received an email from Alex who suggested that I test several

shaft cleaning and conditioning products. His request reminded me

that I had begun doing such an evaluation but decided not to pursue

it. After posting questions

about such

products on both the Inside Pool forum and another

billiards

forum I found in a Google search, I discovered that two-thirds of

the comments

about these sorts of products were negative. Most people

stated that

over time these products leave a residue builds up on the shaft which

hinders smooth motion. With so many negative comments I decided this

was one test I

wasn't

interested in pursuing.

This got me thinking about other options for cleaning shafts and made me realize that I'd never had a problem with dirty or sticky shafts. I think the reason is that many years ago I adopted Byrne's recommendation for cleaning shafts: simply rub them gently with a soft green kitchen scrub pad like the one in the picture below.

Although these pads feel rough, they are much softer than the wood cue shafts are made of, so unlike sandpaper it can't abrade the surface and slowly wear down the shaft's diameter. I used pads like this on my old cue for 15 years and it kept it clean and smooth and didn't change the taper by the slightest amount. I cut a 2 x 4 inch strip from one of the pads to make it easier to handle. One such piece will last for years and through use softens so it's even gentler on the shaft. These pads seem to accomplish two things. First, they remove any dirt and oil deposited on the shaft. Second, they burnish the wood so that it becomes smoother. I've never seen a trace of sawdust from using one of these pads.

One nice thing about trying a goofy idea is that even if it doesn't work it's still entertaining to read about the failure. What follows is such a case.

Thinking that an ultra resilient cue tip might generate more spin, I got the idea to carve one out of a super ball, one of those high density plastic balls that bounce much higher than normal rubber balls.

I began by purchasing eight of the smallest super balls I could find and testing them to select the one that bounced the highest, then used a razor blade to slice off a section.

Next, I traced

around an real tip to create a cutting guide for trimming the tip to the

13 mm diameter

of the test cue.

The completed tip was rough and the curvature was the diameter of a quarter instead of the preferred nickle (or dime if you're one of those.)

The pink color looked odd, but chalking should hide most of that. I glued the tip to the test cue (I'm crazy enough to think up something like this but not crazy enough to put it on my good playing cue) using Tweeten's 10 minute tipping cement.

How did it play? Strange... very strange. All shots generated a vibration that ran up and down the cue. This makes sense because the plastic tip would naturally deform more then spring back slower than a leather or phenolic tip. Without chalk, English shots easily put two to three times the amount of spin on the cue. But, they also had a sticky feel as if the tip didn't want to let go. Chalking eliminated this but also reduced the spin. Weirder still was the fact that squirt went through the roof. I believe this was because the edge of the tip deformed it creating a significantly sharper angle of contact with the cue than with a harder leather tip. Then when it bounced back it pushed to cue ball sideways at this increased angle. The greatly increased spin and squirt would make controlling a cue with a tip like this a nightmare.

Even worse was the fact that the tip self-destructed. Bits of the edge started flying off with the first stroke. I remember when super balls first came out (Yes, I'm old enough to recall that happening.) they had a tendency to explode if thrown down too hard. Once they were cut, this problem became much worse. I believe that slicing the ball created many fracture lines that easily tore loose. The final problem was that the entire tip ended up flying off the cue. The cement I used wasn't formulated to hold this type of plastic.

Oh well, back to the drawing board.

NEW!!! An extreme cure for sweaty hands

For anyone plagued by palms that sweat so much that it makes shooting pool a nightmare, I've heard of a possible cure. Please note that I am not a doctor or in any way connected with the medical profession. I am not recommending any of the following medical procedures.

The following article about excessive sweating contains a reference to a surgical procedure in which the nerve that triggers palms to perspire is cut or cauterized so that the associated palm no longer sweats. However, I don't know what is meant by "palm" in this article. If a "palm" does not include the inside of the fingers and they still perspire after the operation, then this may not be enough of a cure for billiard players. Mention is also made of some medicines that may reduce sweating.

(Note: If you live in hot moist area like Florida, your problem may be related more to environmental humidity than excessive perspiration.)

The following was copied from http://www.sts.org/doc/4097#6, a US government medical information service. Once you get to this site, roam around a little and you may find some other non-surgical options.

HYPERHIDROSIS

Description By: Keith Naunheim, MD

WHAT IS HYPERHIDROSIS?

Hyperhidrosis is a disorder

characterized by excessive sweating that occurs

in up to 1% of the population. The

excessive sweating can occur in the hands

(palmar hyperhidrosis), in the

armpits (axillary hyperhidrosis), or in the

feet (plantar hyperhidrosis).

Although nobody understands the exact cause of

this excessive sweating in

specific individuals, it is known that the

sweating is controlled by the

sympathetic nervous system.

WHAT IS THE SYMPATHETIC NERVOUS SYSTEM?

The human body possesses two

different sets of nerves: the somatic nervous

system and the autonomic system.

The somatic nervous system is the system of

voluntary nerves that give us

sensation (pain, heat, and touch) as well as

the control of our muscles that

allow us to move the different portions of

our body at will. The autonomic

nervous system, on the other hand, is the

involuntary nervous system. Many

of our bodily functions occur without

conscious control such as the rate

at which we breathe, the beating of our

heart, and the production of

sweat, which is important for regulating body

temperature. The autonomic nervous

system is made up of two components: the

sympathetic and the

parasympathetic systems. It is the sympathetic nervous

system that controls the sweating

throughout our bodies.

WHAT CAUSES THE SYMPATHETIC SYSTEM TO MALFUNCTION?

Although there is ongoing research

investigating this abnormality, it is not

known what specific defect occurs

that results in excessive sweating.

Whether it is the over activity of

the sympathetic nervous chain or the

sweat glands themselves is uncertain.

WHAT ARE THE SYMPTOMS?

Patients with hyperhidrosis have

excessive sweating that hampers their

activities of daily living. It is

sometimes brought on by stress, emotion,

or exercise, but can also occur

spontaneously. Patients with palmar

hyperhidrosis have wet, moist

hands that sometimes interfere with grasping

objects. Most patients with palmar

hyperhidrosis also consider it a

difficult social problem since

every time they shake hands, they leave the

other person's palm very moist, a

sensation most people find unpleasant.

Those who suffer from axillary

hyperhidrosis sweat profusely from their

underarms causing them to stain

their clothes shortly after they dress. Once

again, this proves to be very

unsightly and a social disadvantage. Plantar

hyperhidrosis is the excessive

sweating of the feet and leads to moist socks

and shoes as well as increased

foot odor.

WHAT IS THE TREATMENT FOR HYPERHIDROSIS?

The initial treatment for

hyperhidrosis is usually medical and does not

involve surgery. There are

ointments and salves available (i.e., Drysol)

that are astringents that tend to

dry up the sweat glands. Another treatment

is iontopheresis. This consists of

a treatment of electrical stimulation,

usually in the hands. Patients

place their hands in a bath through which an

electrical current is passed. This

treatment tends to "stun" the sweat

glands and can decrease the

secretion of sweat for periods of 6 hours to one

week. One of the most recent

treatments proposed is the injection of

botulinum toxin (Botox) into the

area of excessive sweating. This is a toxin

that affects nerve endings and

decreases the transmission of the nerve

impulses to the sweat glands thus

resulting in decreased sweating. It

generally requires several

injections in the palms or underarms and it

remains effective from one to six

months. Repeated injections are nearly

always required to maintain an

adequate level of dryness.

In addition to the above

treatments, many medicines have been utilized with

varying success. These include

both sedatives (in those patients with

stress-induced hyperhidrosis) and

medications that affect the nervous

system. A family practitioner or

internist often begins the initial

treatment for hyperhidrosis. Cases

not responding to simple treatment

regimens are often then referred

to a specialist such as a dermatologist or

neurologist. In general, surgery

is contemplated only when the less invasive

medical treatments have failed to

provide adequate treatment.

WHAT SURGERY IS PERFORMED TO TREAT THIS CONDITION?

The surgical treatment of

hyperhidrosis involves destroying or removing a

specific portion of the main

sympathetic nerve. As noted above, the

sympathetic nerves are part of a

separate and parallel nervous system. Their

anatomic location is separate from

the somatic (voluntary) nerves that

control sensation and motor

function. The sympathetic nerve "chain" is

formed by a plexus of nerves

located next to the ribs in the chest. The

spine is made up of vertebra,

which are blocks of bone stacked one on top of

another like building blocks. The

branches that form this sympathetic

"chain" come from

between these building blocks and end in a bundle of cells

called a ganglion. There is a

ganglion at each vertebral level of the spine

and all these ganglions are

attached one to another longitudinally to form

the "sympathetic chain."

A sympathetic nerve branch then comes off each of

these ganglions and travels out to

enervate blood vessels and sweat glands

in the body. The surgical therapy

for hyperhidrosis entails removing or

destroying the specific ganglion

that cause sweating in the arm and the

axillae. There are a variety of

ways of dealing with the sympathetic

ganglions including removing them,

cauterizing them, cutting the branches,

and clipping them. Different

surgeons have been trained in different

techniques and all appear to be

effective in a high percentage of cases. No

specific technique has proven

definitively to be superior to the others.

In order to treat palmar (hand)

hyperhidrosis, the T2 ganglion is removed or

destroyed. Many surgeons will also

remove the third ganglion to maximize the

chance of completely preventing

sweating of the hands. In order to treat the

armpit, the second and third

ganglia are removed or destroyed. Similarly,

some surgeons will also destroy

the fourth ganglion to once again maximize

complete relief from armpit sweating.

In the past, this often required a