While I usually spend most of my time figuring out how to blow giant soap bubbles like this...

...I recently became interested in the other end of the size spectrum: how to blow the very smallest soap bubbles. Here's what I discovered:

I started by examining different sizes of bubble wands.

I learned two things: First, that bubble size is only weakly affected by wand diameter. Reducing the wand's diameter by half only reduces bubble size by 10-percent. This told me that to blow the very smallest soap bubbles I was going to need a want diameter that was almost microscopic. Second, when the wand diameter gets very small, the surface tension of the bubble solution is strong enough to create a barrier through which even the fastest bubble machine fan is not going to be able to blow a bubble. The air flows around the wand rather than through it.

These two

issues almost killed the project before it got started. Then I

discovered a YouTube video showing bubbles being blown out of fine straws.

These overcame the surface tension problem by focusing all the power of the air against the bubble solution membrane. But, I could not figure out how to replenish the bubble solution so the tubes could be used in bubble machine and at the same time pump air into the tubes.

The answer was to separate the two.

A normal bubble wand would be circulated through a reservoir of bubble solution to create the bubble solution membrane from which the bubbles could be blown. A fine tube positioned close to it would blow a stream of air through the membrane to create the bubbles.

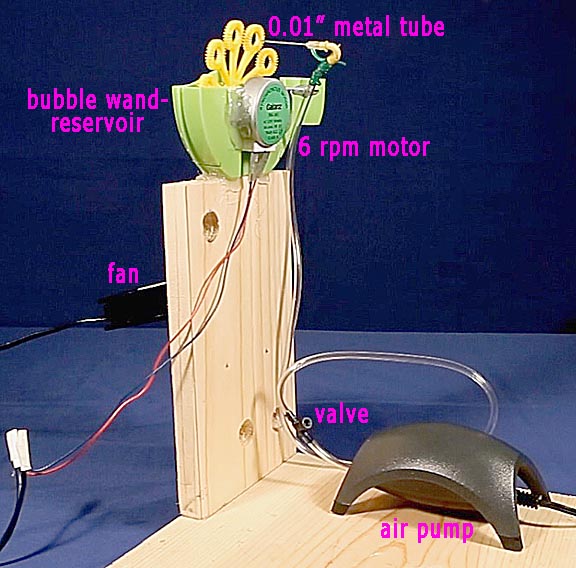

Armed with this concept I built the following bubble machine:

The air pump is an inexpensive aquarium pump. Air from it passes through an aquarium air valve to control the flow rate. The air is carried up through 1/4-inch tubing to the working end of a Blas Fix Egg Emptier. This device is used to remove the liquid interior of eggs prior to decorating. It was the finest metal tube I could find that produced acceptable bubbles. I say 'acceptable' because after experimenting with finer tubes, at one point I used the needle from a hypodermic syringe, I discovered that they all produced bubbles that were so small they no longer looked like bubbles. They had no color and appeared more like large dust particles than anything else. At this size they also represented a inhalation danger. Tubes larger than the 0.010 inside diameter tube created larger bubbles and also transmitted so much of the pump's reciprocating pulses that the bubble solution membrane was ruptured before any bubbles could be produced. These larger tubes could be made to work if the air was first pumped into a 2-liter bottle where the volume created a plenum effect that removed the pressure pulses.

The bubble solution reservoir and circle wand were scavenged from a Gazillion Hurricane bubble machine. The wand was driven by a 6 rpm motor removed from a microwave oven. A computer cooling fan was used to blow the bubbles up into the air. Because they were so small, they had a much higher surface to volume ratio than normal bubbles. This made them proportionally heaver with the result that they fell down very quickly. With the fan, half of the bubbles were thrown high enough into the air to create an entertaining cloud of mini bubbles.

I tried adding a tee to the airline so helium could be added to make the bubbles float. It didn't work. While some remained in the air a little longer, getting the proper flow setting was very difficult and shortly after doing so, tank pressure would decrease enough so that it would have to be reset. It wasn't worth the effort.

While fine tuning this machine to produce the smallest possible soap bubbles, I discovered that besides tube diameter, air flow and tube position also affected bubble size.

For any particularly tube, there was one flow rate that produced the smallest soap bubbles. Rates higher or lower increased bubbles size.

The closer to the bubble solution membrane the tube could be positioned, the smaller the soap bubbles would be. The minimum distance was determined by wand thickness. Smaller soap bubbles could be produced if the back side of the wands were sanded down so the rear surface was flat, allowing the tube to be positioned closer to the membrane.

One final trick to improve bubble production was to use inexpensive bubble solutions instead of high end solutions like Gazillion and BeeBoo. The cheaper brands are thinner and in this application produce more bubbles and cause less foaming in the reservoir.

Here's what it looks like in operation:

The smallest dots are bubbles only 1/16-inch in diameter. The average bubble is 1/8th inch across. The largest bubbles are actually clusters of smaller bubbles. The bubble machine pumps out thousands of these tiny bubbles every minute.

The novelty value of a room full of the very smallest soap bubbles is great for children's parties.

If you'd like to see the machine in operation, please click on the following link:

This second video shows and explains how bubbles this small form:

Anyone prefering not to use YouTube, the following still image captures most of the detail:

A stream of air from the left blows through the membrane of bubble solution stretched across the wand, creating a long tube of solution. Eventually, turbulence in the tube forms a narrow neck. The bubble solution's surface tension causes this neck to be pinched off, creating a new bubble. This process repeats hundreds of time a minute. As the neck is pinched off and the bubble moves away, a thin thread of solution is stretched out between the bubbles. I've seen as many as six bubbles connected by such threads. For scale, the bubbles in this image are one millimeter in diameter.

Thanks for visiting!

Return to my main page to browse 60 other subjects