Five Tricks to Improve an Inexpensive Inkle Loom:

I was watching my wife work her inkle loom one day and thought of several simple changes that would make it easier for her to use. With her permission I implemented them and I'm happy to say that they all worked. I'm posting them here for anyone who might be interested.

1. The first thing I noticed is that the screws holding the frame to the base weren't countersunk.

This caused them to stick out, scraping table tops whenever she put the loom down. The simple solution was to remove the screws, carve out a countersink by twisting the tip of a carving knife in the screw hole

and then replace the screw. No more scratched tables.

2.

Next I observed that warp tension was bending the front dowel inward

so much the yarn was starting to slide outward. I removed the dowel,

reglued it with a good quality wood glue, then braced it with a

diagonal dowel.

The front dowel is now rock-solid and shows no sign of bending.

3.

Because the loom had such a small base it was hard to balance on my

wife's lap. Screwing it to an eight-by-twelve inch piece of one-inch

thick pine solved that problem.

4.

Although my wife had no problem cutting many pieces of yarn all the

same length to make the leashes, after tying them they all came out

different sizes. This looked sloppy on the loom and some, which were

much longer than the others, resulted in the yarn associated with

them to be held high enough above the rest that from time to time

they's snag the shuttle.

To make sure all the leashes were all the same length I made a set by tying them across the long length of a credit card. The problem was that no matter what type of knot I used there was always slippage of varying amounts that caused the leashes to once again come out different lengths. The solution was to stick a piece of double-faced carpet tape on the credit card to hold the first knot in place while the second knot was cinched down on it.

The

black arrow indicates the tape.

With

this system we were able to quickly and easily make two dozen

leashes that were all exactly the same size.

5.

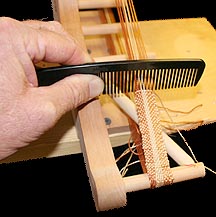

Finally, no matter how carefully she beat down the weft, it was

always uneven and tended to draw in the sides of the warp. The simple

solution was to purchase a cheap selection of combs, $1.88 at

Wal-Mart, and sort through them to find the one with a tooth spacing

matching the warp.

It worked! The comb beat the weft into the warp much straighter than using the shuttle and greatly reduced the amount the weft pulled in the sides of the warp.

I

sincerely hope that anyone visiting this page found it useful and if

they haven't done so already, will pay my main page

a visit where they will find several other weaving-related pages and

over 100 pages covering many other topics: everything from gardening

to kaleidoscopes.