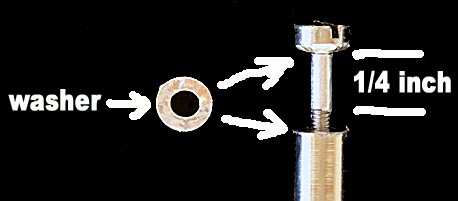

Painting the axle hub white makes placing an alignment mark on it easy. This

records where the axle is aligned, which allows removing and replacing

the same axle without affecting the car's alignment.

Wayne Schmidt's Awana Grand Prix Race Car Page: How to build the fastest Awana pinewood race car.

Introduction:

My interest in Awana Grand Prix racing began when my grandson asked me to help him build a race car for a Spring competition. My only previous experience with pinewood-type race cars was 25 years earlier with my son. Since we didn't do very well back then I decided a little study was in order to learn how to build the fastest possible Awana car. This proved be a frustrating venture because while there are a dozen books on the subject of pinewood racers and hundreds of web sites, the problem with all of them is that while they told me what to do and offered some explanations why it should be done that way none provided experiments to verify that the advice they provided was valid. This is critical because many sources offer conflicting advice. (The one exception to this is the excellent DVD titled Physics and the Pinewood Derby by Dr. Scott Acton, a physicist at Ball Aerospace Laboratory. This video provides the science behind building lightning fast pinewood race cars in a thoroughly entertaining and enlightening mix of experiments and practical advice. While I reference this DVD many times on this page, this video covers a wealth of additional information not mentioned here that is worth the purchase price many times over. I strongly recommend that anyone seriously interested in building a fast Awana Grand Prix race car, or any pine wood race car, purchase this DVD. It's available from many sources including Dr. Acton's web site at www.pinewoodphysics.com.)

This page digs deep into the physics that affects how fast a pinewood derby car goes. Anyone more interested in the nuts and bolts of simply building a fast car, I recommend they try the construction page at: HOW TO BUILD THE FASTEST PINEWOOD DERBY CAR.

Before we start building the ultimate Awana Grand Prix racer, a little background is appropriate.

Awana, (Approved Workmen Are Not Ashamed) is a non-denominational, Christian youth organization similar to the Boy Scouts of America in that it strives to promote responsible development in children. One of the programs they support is the Awana Grand Prix race every Spring. Participating children purchase Awana Grand Prix car kits, build their cars with the help of their parents or other relatives and race them at a church participating in the Awana program. The car kits are almost identical to Boy Scout pinewood derby kits in that they consist of a pine block measuring approximately 7-inches long, 1.75-inches wide and 1.25-inches tall, four wheels embossed with the Awana Grand Prix logo and a set of axles.

The biggest difference between Awana Grand Prix car kits and all the other variations of pinewood race cars is that while many programs use simple nails for axles, the Awana car kits use small hinge pins. This has a profound effect on one of the critical aspects of car construction: axle polishing. This topic and many others will be researched and discussed in detail further down the page.

A lot of what follows is painfully detailed so let's start off with something lighter. The following video shows the favorite cars in my collection. I hope you enjoy them.

Here's one more you might enjoy:

So much for fun. Let's get started!

Methodology:

The times reported in the various tests on this page are for cars running on my track at home and are for comparison purposes only. If they appear slow that is because the vinyl surface on the track has a slight texturing that causes it to run slower than polished plywood tracks and much slower than aluminum tracks. Additionally, while most 32-foot tracks have actual run lengths of 30 feet or less, mine has a run distance of 31.1 feet. Finally, the start end of most tracks is 48 inches high. Mine is only 44. All these factors add up to a very slow track. For comparison, I made a car identical to one used by Dr. Acton for his DVD and discovered it ran 0.030 seconds slower on my track than on his. The conclusion is that if some of the times reported for what I consider a very fast car sound slow, it's because of the track.

It is my intent to provide experimentally verified information to help people construct the fastest possible Awana Grand Prix car. Readers are provided with the raw data as well as the experimental methodology so they can decide for themselves if the conclusions are valid.

The methodology used to compare speed techniques was to run a set of ten runs with the car in its normal configuration, make the change to be tested being careful to keep everything the same, particularly alignment, then run a second set of ten runs. The times for the two sets are averaged to determine if there is a significant difference. The track is vacuumed before every set of ten runs to avoid dust buildup, which can effect times. For the same reason, wheels were wiped off to prevent imbedded grit from slowing the car by roughening the wheel surface. As an example, the following experiment determines the error between tests:

The same car was raced with no changes made between sets except that fresh graphite was added at the beginning of each set of ten runs:

Run Set 1.....................Run Set 2

2.542

seconds..................2.531

2.569..............................2.563

2.558..............................2.545

2.553..............................2.557

2.564..............................2.540

2.544..............................2.564

2.547..............................2.541

2.550..............................2.560

2.553..............................2.551

2.542..............................2.553

2.552 seconds average....'..2.550 seconds average

The 0.002-second difference suggests that when comparing speed techniques, unless the technique being tested shows an improvement greater than this then it is impossible to claim whether it works or not. This criterion is used throughout this page to judge whether a technique is worth applying. I'll be the first to admit that larger test runs should be used but I had to compromise some accuracy due to time constraints. It's important to understand that the test results reported are for my cars running on my track. Other people using different equipment may obtain varying results.

The biggest source of inaccuracy with this technique is axle alignment changes in those tests where the wheels have to be removed. Marking the axle heads helps return them to their original alignment.

Painting

the axle hub white makes placing an alignment mark on it easy. This

records where

the axle is aligned, which allows removing and replacing

the same axle

without affecting the car's alignment.

I always test

the alignment by running the car down an inclined flat board. If the

car swerves off a straight line it is realigned so that it tracks as

straight as it did before the axles were removed. Test runs confirm

that the average change in run times before and after axle removal is

0.004 seconds. If a speed technique produces a change that is smaller

than this then no judgement can be made regarding its efficacy.

The timer used for the experiments was a Timestopper TS100-2 running 3.0A software. It measures to 0.0001 seconds and rounds to display to 0.001 seconds.

Sometimes there are changes in run times between large groups of tests. For example, run times increase between the sequence of test runs comparing Max-V-Lube, Hillmand and Hub-E-Lube and the follow-on sequence of test runs comparing Max-V-Lube, Super-Z Graphite and Super-Z Graphite with oil. The cause of this was a change in the configuration of the track. For this reason comparisons across different groups of tests should be approached with care.

Major topics

are bookmarked so that visitors may quickly skip down to the article

they want. The first line in each article is a summary of results so

readers can get the answers to their questions as quickly as

possible. Following this summary are the experiments and analysis

that provided the conclusions in the summary.

Several products are mentioned on this page. I have no connection with any of these products or the people who market them. No one is has paid or asked me to mention them.

The topics are ordered with the most important speed hints listed first. I hope you find them helpful and wish you all good racing!

Topic List:

Graphite: Why it's the single most important factor, what types to use and how to apply it.

Axle Alignment: How two wrongs make a right.

Center of Mass and Moment of Inertia: Understanding these two concepts is essential to building the fastest car.

Axle Treatments: How much polishing helps, what about hub coning and do slots really reduce drag?

Wheel Treatments: The dangers of wheel mandrels, does bore polishing help, graphite coated wheels, rim smoothing, the spin-up myth, hub coning, and are $40 lathed wheels worth it?

Three Wheel Cars: How much faster are they?

Extended Wheel Bases: How much do they increase speed?

Rail Riders: Do they really make the fastest cars?

Hub Huggers: Myth or fact?

Quick Start Wings: Do they really provide 0.010-second head starts?

To Bake Or Not To Bake?: Cooking your car may reduce it's weight, but is the risk worth it?

But Dad, I really want fins: A hard look at aerodynamics.

The Shock Absorber Design: Do flex-bodies really help cars run smoother and faster?

Rules: A typical set of rules for Awana Grand prix races.

Putting It All Together: My fastest car.

How Fast Is Fast?: How fast they go.

When Good Cars Go Bad: How a speed demon can turn into a dog.

But I Was Winning!: The dynamics of racing.

Building a Super-Cheap Track for Home Use: Would you believe a 32-foot track for $20?

Want a Super-Cheap Timer to Go with that Super-Cheap Track?: It'll cost another $30.

Odds and Ends: Useful bits and hints.

Are Dr. Scott Acton's Cars Really the Fastest Cars?

Treadmill Tuning: Does it really help?

Bibliography: The sources referenced in creating this page.

Graphite:

Summary:

a.

Using graphite is the most effective way to increase car speed.

b. Max-V-Lube

gives

the best times.

Nothing is more important than having a good layer of graphite on your car's axles. I've had cars that were out of alignment, had bent axles, wobbly wheels, poor centers of gravity and insufficiently weighted, but as long as they had a liberal coating of graphite they somehow managed to make it to the end of the track. I've also had class-A speedsters that rolled to a stop halfway down the course because I failed to graphite their axles.

The two big questions are: What type of graphite is best and what is the best way to apply it?

To answer these questions I drafted my oldest grandson's car to test three common brands.

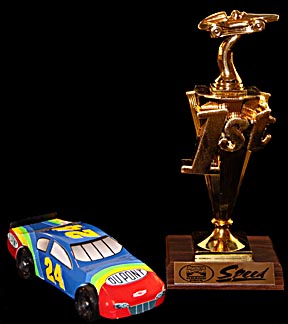

Joshua

named his car Lighting

Quick, and it's an appropriate name.

It's

been the Grand Champion at several family races.

The first three graphites tested were: Hillman (graphite for locks), Hob-E-Lube (graphite and molybdenum mix) and Maximum-Velocity's Max-V-Lube (pure graphite.)

Max-V-Lube was many times finer than the other two and the container comes with a long thin tube that makes reaching into tight area around axles easy.

How

To Apply Graphite:

There are six surfaces that have to be coated with graphite: the axle, the wheel bore, the area of the car body that contacts the inside hub of the wheel, the inside wheel hub, the outside wheel hub and the inside face of the axle hub. To insure that all six surfaces get the same treatment I adopted the following routine:

1. With a wheel down to expose the inside section of axle, I build up a fillet of graphite all the way around the inner wheel hub.

I then press the wheel up against the car's body and twist it back and forth four times to work graphite into the body's surface and the inner hub face.

2. I build up another fillet and this time tap the wheel lightly with a fingernail ten times to enable graphite to work into the gap between the axle and wheel bore.

3. The car is turned over and both steps repeated for the outside of the wheel.

For

the test I began by removing the wheels, scrubbing the bores clean

with a cotton pipe cleaner, wiped off both wheel hubs and the hub

contact point on the car's body and carefully cleaned all traces of

graphite off the axle. This process was repeated for all four wheels

then they were regraphited with the graphite to be tested. Then the

car was run down my test track 10 times, recording the time of each run.

Here are the results of the graphite tests:

Hillman ..........................Hob-E-Lube .....................Max-V-Lube

2.564

seconds....................2.544..............................2.542

2.550................................2.528..............................2.554

2.537................................2.527..............................2.539

2.541................................2.532..............................2.533

2.547................................2.546..............................2.510

2.516................................2.559..............................2.535

2.529................................2.550..............................2.537

2.547................................2.570..............................2.542

2.552................................2.561..............................2.541

2.577................................2.551..............................2.547

2.546 seconds average......'..2.547 seconds average...'...2.538 seconds average

It

may not seem that Max-V-Lube's 0.008 and 0.009-second advantages are

significant, but at an average speed of 13 feet per second this

corresponds to a lead of 1.2-inches at the end of a race, more than

enough for an electronic timer to signal the Max-V-Lube car the winner.

Shortly after finishing the test above I read an article about Super-Z graphite and Super-Z oil which, when used together, were claimed to produce a super low coefficient of drag and therefore very low race times. Carefully following the manufacture's instructions for using these products I conducted the following tests:

Max-V-Lube ................Super-Z

Graphite ....Super-Z

Graphite and Super-Z Oil

2.766

seconds....................2.785..............................2.931

2.740................................2.812..............................2.925

2.740................................2.827..............................2.933

2.740................................2.835..............................2.891

2.753................................2.822..............................2.901

2.745................................2.837..............................2.918

2.747................................2.812..............................2.875

2.744................................2.823..............................2.867

2.736................................2.816..............................2.894

2.739................................2.832..............................2.900

2.745 seconds average........'2.820 seconds average......2.903 seconds average

These tests strongly suggest that Max-V-Lube is superior. The very large flakes of Super-Z Graphite were extremely difficult to use and the application process much more involved than that of the other graphites tested. (Note: The increased times over the first set of tests were the result lowering the starting end of the track. Also, even if the Super-Z oil had worked, most Awana Grand Prix races only allow graphite.)

Graphite

Types:

From left to right: Hillman, Hob-E-Lube, Max-V-Lube, AGS Ultrafine Graphite, 0.6 micron Tungsten Disulfide, Super-Z Graphite

Smearing each with a finger disclosed some interesting comparisons. Hillman, Hob-E-Lube and Max-V-Lube all smeared smoothly. (Max-V-Lube has a granular, almost crystalline appearance.) AGS Ultrafine looked clumpy and felt a little gritty. Where I first pressed my finger it left a clump of compressed material that was hard to dislodge. The tungsten disulfide looked extremely clumpy but smeared the smoothest of all. (It's reported to be twice as lubricating as graphite.) Super-Z had very large, hard to control flakes that nevertheless smeared smoothly.

Comparing

Max-V-Lube to AGS Ultrafine Graphite and Consolidated Chemical's 0.6

micron tungsten disulfide lubricants:

Max-V-Lube .................AGS

Ultrafine ................Tungsten

Disulfide

2.712

seconds....................2.785..............................2.921

2.701................................2.813..............................2.911

2.698................................2.804..............................2.924

2.710................................2.818..............................2.930

2.704................................2.797..............................2.917

2.709................................2.806..............................2.898

2.713................................2.811..............................2.904

2.707................................2.798..............................2.911

2.698................................2.801..............................2.916

2.704................................2.810..............................2.902

2.706 seconds average......'..2.804 seconds average...'...2.913 seconds average

AGS Ultrafine and tungsten disulfide did very poorly in part because they were so fine they clumped and were impossible to coat the axles. I repeated the test, this time breaking the established application protocol by removing the axles and rubbing AGS and Tungsten disulfide directly onto the axle shafts and wheel bores. That did not change the results. After completing these tests I found another ultrafine graphite sold by Consolidated Chemicals. Like the AGS Ultrafine, it did very poorly when compared to Max-V-Lube. Another problem with ultrafine graphites is that they are so fine that if spilled on almost any surface they get pulled into microscopic pores and become messy and difficult to remove.

Max-V-Lube has proved itself superior to seven other lubricants so it's the one I'm using from now on.

Axle Alignment:

Summary:

a.

The axle slots and predrilled holes in commercially produced Awana

or pinewood derby blocks are not accurate enough for optimum performance.

b.

Pro body tools for guiding drill bits for drilling axle holes are

far too inaccurate.

c.

The best way to mount axles is in holes drilled with a drill press

that's been set up to create holes that are within 1/4-degree of perpendicular.

When I began making Awana Grand Prix cars I just about went crazy. My cars always swerved off to one side or another. My only recourse was to go through an arduous process of axle bending to get them to track straight. After countless hours examining the problem I discovered that the predrilled axle holes and precut axle slots in the blocks I was buying were as much as 2 degrees off perpendicular, even on the high-end precision-cut blocks available on-line.

I tried using a pro body tool to act as a guide for drilling holes that were more perpendicular to the sides of the block. It made things worse.

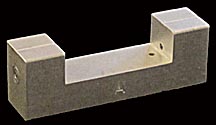

Pro

Body Tool

The

hole for guiding the drill was large enough that the drill bit could

lean two degrees off perpendicular.

I decided that the only thing to do was buy a drill press. It didn't help. I quickly discovered that the adjustments on it were far too coarse to achieve the 1/4-degree accuracy required. But at least the drilling surface was stable and the drill head fixed. I learned that by using layers of tape on the drill bed to shim the back and sides of a wood base I could finally get the press to drill axle holes that were almost perfectly perpendicular to the sides of the block. I grabbed a block, threw on the press's switch and drilled four beautiful holes. Two minutes later I'd mounted wheels on it and let it roll down the alignment board (a 10-foot long by 6-inch wide piece of vinyl coated molding with one end elevated 5 inches) and watched in horror as the car swerved sharply to the left and fell off the board before it traveled three feet.

After examining the problem I discovered that even the best Awana and pinewood derby blocks don't have truly perpendicular edges. They all have slight tapers that give them trapezoidal cross sections. Even though the holes on one side were perpendicular to that side, because that side wasn't parallel to the opposite side the axles on the second side aren't parallel the axles on the first side. I was about to give in to the inelegance of bending axles to achieve alignment when inspiration struck.

If I mounted a wood fence on the drilling base that was perpendicular to it then held the bottom of the car block against it, rather than the side of the block against the bottom of the drill press platform which is more typical, then all four axles would be drilled relative to the same surface: the bottom of the block.

To check the accuracy of the holes, something I do using a test block before drilling the real holes in a car, purchase a 3/32-inch brass rod from a hobby store. After a little sanding on one end with 400-grit paper it should slide down very snuggly into an Awana-sized hole. Using one edge of a very accurate architect's triangle, hold it against the base of the block and check to make sure that the separation between the rod and triangle is constant all the way up the rod's 12-inch length. Then use the right angle of the triangle with one side parallel to the long edge of the block and check that the rod is perpendicular that way as well. (Check the rod's straightness by rotating it in the hole. If the angle relative to the edge of the triangle remains constant it's straight. I'm always careful to hold the block so the rod points straight up. If it's leaning the rod could flex enough to throw the check off.) If the rod shows the hole is straight you're good to go. If it shows an angle then add or remove shim tape to correct it. As simple as this system is it can repeatedly drill holes that are with 1/4-degree of perpendicular.

It worked... almost.

The first car I built using this system rolled down the alignment board swerving just 2-inches in ten feet. Good, but not good enough. I thought I was doomed to descend into axle bending when inspiration struck for the second time. This time it was the realization at at least as far as pinewood race cars are concerned, two wrongs really do make a right.

The first "wrong" is that no axle hole will ever be perfectly perpendicular. The second is that no axle is perfectly straight. Realizing that the very small amount of bend in all axles is on the same scale as the very slight off angle of the axle holes, I realized that if the axle was rotated so that its bend turned the axle in the opposite direction that the axle hole pointed it then the two defects would cancel.

It worked. I began turning the front right axle a quarter turn at a time and on the second turn the car ran straight down the alignment board. It was beautiful. I made two more cars the same way. The first tracked straight the first time I tested it and the other only took three twists to get it to run straight. I was riding high thinking I'd conquered crooked axles forever. Then everything went horribly wrong.

I drilled the holes for a new car, put it on the alignment board and watched in horror as it swerved sharply right. No amount of axle turning would solve the problem. What had happened?

Nature happened. Wood blocks have grain: alternating layers of soft, light wood and hard, darker wood. If the drill hits a layer of hard grain at a small angle the bit will bend as it slides along the hard wood and drill a curved hole.

The

white line represents the path of the drill as it's deflected by a

layer of harder wood.

Normally

this isn't an issue but the thin drills used for Awana axles bend

very easily.

When an axle is inserted in such a hole it'll end up coming out at a slight angle. You can feel this when inserting an axle because instead of sliding in snuggly it has to be pressed in very firmly.

To reduce this problem, stub bits short in the chuck so that only the absolute minimum needed to drill the axle hole is exposed. This effectively makes the drill stiffer. Select wood with the grain as close to perpendicular to the direction of the drill as possible. Drill with a high rotation speed so the drill has more cutting strength to help it pierce the hard layer. Finally, drill very slowly so the bit has enough time to grind through hard layers. I usually take one minute to drill an axle hole that's only 1/2-inch deep.

Another useful trick is to avoid drilling axle holes right next to the edge, as pro body tools do. The problem is that wood is flexible enough that while drilling it will actually bulge out. You can feel this happening if your finger is over that spot. By moving the axle hole 1/8-inch from the edge the extra thickness provides enough strength to prevent this and yield straighter holes.

Once the axle holes are drilled it's time to align the axles in them so the car runs straight. Rough out the shape of the car first to relieve any internal strains that might throw alignment off. Polish and lube the axles before alignment because axle drag can be enough to turn the car even if the axles are perfectly aligned. Place a weight on the car near the rear, remove one of the front wheels and roll the car down the alignment board. If it curves, rotate the axle 1/4-turn and try again. Usually, before you get back to where you started you'll find a position where the car tracks straight. Don't be afraid to play with the rotation. Sometimes a tiny fraction of a turn makes the difference between a car running arrow straight and curving. Use a permanent marker to make a mark at 12:o'clock on the axle head so you know that axle's alignment position and remove it. Repeat the process with the other front wheel then test them together. When they are done turn the car around, move the weight to the new rear end and repeat the alignment with the rear (now front) two wheels. Replace all the wheels using the axle marks to get them back to their properly aligned positions. Check the car one more time and you should be good to go. Remove the wheels and finish the car. The alignment needs to be repeated after the car is finished because all the handling might warp the wood slightly.

Cars can be made to roll straight by leaving all four wheels on and playing with the axle rotations. This saves the hassle of aligning each wheel by itself but it may end up being a car that rolls very straight... and very slow.

What can happen is that two wheels can be off angle by the same amount but in opposite directions. In other words the car is pigeon toed. One wheel wants to turn the car left while the other wants it to go right, both by the same amount so they cancel each other and it goes straight. The problem is that because the wheels are pushing against each other the wheel drag goes sky high and the car never runs as fast as it should. (Dr. Acton's DVD shows how to make a jig for testing axle alignment.)

If you find that axle rotating doesn't quite achieve the alignment needed, try using a different axle. There is always some variation in manufacturing error and a different axle may have enough natural bend to get the car running straight.

Once in a while I end up with a hole that's just too crooked to deal with by rotating the axles. The best course of action is to start over with a new block and hope for straighter axle holes. But if you've invested a lot of time and money in the existing car then there is no other course other than axle bending. After aligning all the other wheels, remove the offending axle and wheel. Hold the axle in a pair of long nosed pliers just below the area where the wheel rides and using a second pliers, bend the bottom of the axle "very slightly." You shouldn't be able to see the bend. Reinsert the axle and wheel and continue the alignment. Bending is a very powerful technique. Usually, the amount of bend is many times what's needed so the angle over which the wheel is aligned is very small. It can be frustrating when a tiny rotation of the axle results in the changing the car from swerving hard right to hard left.

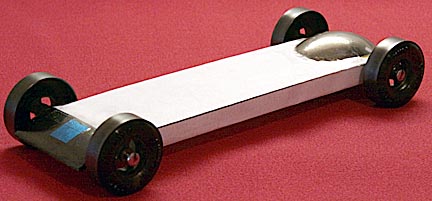

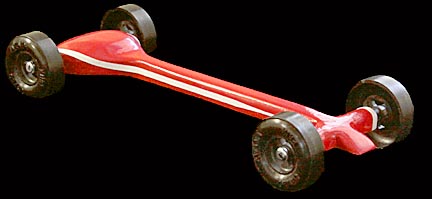

All

of the above has worked great for me for building many solid body

cars like this:

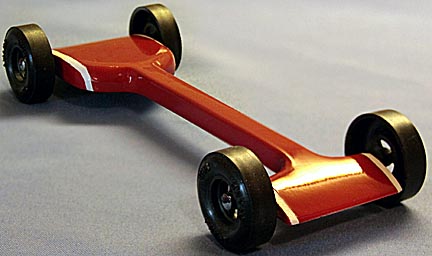

It

doesn't work as well with more complex high performance cars like this:

Grandson

James' Dale Sr. blows past even the very fast Lightning Quick.

The reason is that so much wood is removed after the axle holes are drilled that the wood that's left invariably warps. Drilling the holes after final shaping isn't always possible because there's not enough left of the base of the car to act as a reference plane. This is one of the frustrating aspects of building a top performer, as the following car demonstrates:

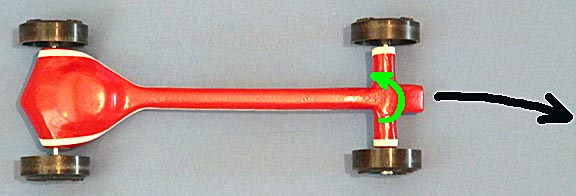

After

drilling the axle holes and epoxying the tungsten weight in the car

above, I carefully aligned it. Going forward or backward it tracked

perfectly straight. Then I proceeded to gently remove all the wood I

could to make it the high performer I hoped it would be. After it was

complete I placed it on the alignment board and as expected, it

failed to track straight even though I'd positioned the axles using

marks I'd put on them after the first alignment. I had expected as

much and started realigning it. In the end I got it pretty good...

but "pretty good" isn't good enough for a car intended to

be a winner. No matter how much I played with the axles the best I

could do was reduce a swerve to the right to 1.5 inches over ten

feet, as indicated by the black arrow. I was about to resort to the

brute-force technique of axle bending when it occurred to me that the

amount of misalignment was so small that there might be enough

flexure in the wood itself to fix the alignment. I held the car body

in my left and and with my right grabbed the front axle section,

gently twisted it in the direction of the green arrow and held it

there for a count of 20. It worked. The car now tracked absolutely

straight. Better still, half an hour later it was still running

straight so it seems this is a long term fix.

For cars with bodies whittled away enough to have some bendability, gently twisting the front in the opposite direction of a persistent swerve might help provide a final touch-up to alignment. But be warned, the front ends of such cars are extremely fragile so don't use too much muscle or you may break it off. Also, be sure to check the alignment right before a race to verify that it's held. The front end's flexibility should be kept in mind when handling the car. Carrying it by the front may throw the alignment off.

In rare cases a car will start swerving one direction, straighten out, then turn in the other direction. I believe what is happening is that a misalignment is turning it one way but as it gets into the bottom half of the alignment board a speed related friction factor on one side begins dominating the car's motion and turns it back the other way. Try using a new set of axles and wheels to correct the problem. If it persists it might be best to start over and build a completely new car.

(Note:

Always keep a log for each car recording how each axle affects

alignment. If

you get the chance to test your car on the

track before a race you can use the log to fine tune the car. Also, in

his DVD Physics and the

Pinewood Derby, Dr. Acton

presents an outstanding way to build cars with an adjustable

alignment system.)

Conclusion: Thorough wheel alignment can be a challenging task, but one that is absolutely essential for building the fastest possible Awana Grand Prix race car.

Center of Mass and Moment of Inertia:

Summary:

a.

Build your

car so that it balances 0.9 inches in front of the rear axles.

b.

Concentrate

as much weight as possible in as small an area as possible.

Where

to Locate Your Center of Mass:

The center of mass of a car is simply the location where it balances.

Typical

Awana Grand Prix cars have their center of mass, where they balance,

located

close to the center of the car.

This

car has its weight moved toward the rear so where it balances, the

location

of its center of mass, is also closer to the rear. Note that the

center

of mass is not where the lead weight is located but the

balance

point for the combined car body and lead weight.

All the energy to make an Awana Grand Prix car go fast is determined by how much it weighs and how far this weight drops as the car races down the track's initial incline. The maximum weight allowed is five ounces so there's not a lot we can do about that. What we can affect is the distance through which this weight drops as the car rolls down the start ramp. The starting post that a car rests up against before being released is usually 48 inches above the flat section of the track. The center of mass of the car is typically four inches behind this. Correcting for the angle of the track the car's center of mass is actually three inches higher, around 51 inches. But, if the front end of the car is made lighter then more of the allowed five ounces can be located in the rear of the car. This moves the center of mass back to as much as five inches behind the starting point or four inches straight up. Now instead of 51 inches of drop distance the car's center of mass has 52 inches.

........

........

Here

you can see that moving the weight back moves the center of mass

higher on the

track.

As the car on the right races down the incline more of its weight

will fall a greater

distance,

which will push the car to a higher speed than the car on the left. This

is

not a subtle effect. Rear weighed cars hit the bottom of the incline and

explode

off the ramp like a turbo boost kicked in. You can hear it as

they

take off with a whoosh.

The extra inch higher of the center of mass of the car on the right represents an almost a 2-percent increase in energy. That means it will end up going 2-percent faster than the car on the left. Instead of an average of 13 feet per second it'll average 13.26 feet per second, enough to finish 8.4 inches ahead of the right hand car. That's over a full car length, a clear victory in anyone's eyes.

So we want to put as much weight in the rear of the car as possible. Or do we? Considering the following poor little car:

I cut the entire end off this guy and replaced it with a solid slab of lead. The car had an extremely low-drag profile, good wheels and excellent alignment. I figured it was going to be a speed demon. It was a dog

The problem was that I moved the center of mass so far back that the front end didn't have enough weight to keep it on the track. The car swerved all over its lane, hitting the guide rail at least a dozen times and barely managed to cross the finish line.

So, we want the center of mass as far back as possible to get as much speed as possible, but we don't want it too far back or the car will become unstable and zigzag all the way down the track. What's the optimum position for the center of mass? I'm sorry to say there's no magic number because it depends on the track.

Very smooth tracks don't subject cars to many bumps so the center of mass can be moved back as far as 0.75 inches before stability problems appear. Old wood tracks with dips at every seam need the center of gravity more forward to help hold the car's nose down. A full inch is a good starting point for such tracks. If you don't know the condition of the track on which you'll be racing a reasonable compromise would be 0.9 inches, about 7/8 inches.

The

key to maximizing the weight toward the rear of the car is removing

as much weight as possible everywhere else. This translates into

carving away all the wood you can. Here's an example of a body that's

been pared down to practically nothing so that most of its weight,

the tungsten disk in the rear, is as far back as stability permits:

This body weighed a scant 8.9 grams, not counting the tungsten weight. The small nose section extending just forward of the front wheels is there to take the impact of stopping the car and and trigger the optical sensor at the finish line. It's width was determined by measuring how narrow it could be and still trigger the sensor even if the car was angled the maximum amount either way. (Note: another price you pay for making a high performance car like this is that the body is extremely fragile. If dropped it will almost certainly break. Also, the front wheels can be knocked out of alignment by smashing into poorly designed car stops, like the pile of bean bags used in one Awana race I attended.

One final weight question: Is it worth it to fine tune the overall weight (mass actually) to be as close to 141.7 grams (5 ounces) as possible? The answer is a definite "yes," as the following test confirms:

Car

at 140.6 grams: .........Same

Car at 141.7 grams

2.720

seconds............................2.701

2.716........................................2.717

2.721........................................2.695

2.726........................................2.716

2.723........................................2.713

2.721........................................2.726

2.710........................................2.712

2.722........................................2.721

2.727........................................2.716

2.715........................................2.724

2.721 seconds average.................2.714 seconds average

The

0.006 advantage is small but equates to a 1-inch lead at the finish

line, more than enough to signal it the winner. (Care was taken to

add the weight in such a way that the aerodynamics, wheel alignment,

moment of inertia and center of mass were not altered.)

Here's another trick about weight. Many AWANA and pinewood derby races are managed by the same people year after year. To make setup easy, it's common for them to have everything needed for a race collected in a "kit," boxes of stuff for the race. One such item is the scale. If you're planning on participating for several years, note what maximum weight gets passed. In the local AWANA races, the scale passes anything up to 143.7 grams. That's 2 grams heavier than 5 ounces. I always weight the cars to this to get as much speed as possible. But be able to peel off or add a couple of small trimmer weights in case they recalibrate the scale.

Moment of inertia:

Moment of inertia is simply a number representing how hard it is to rotate an object.

Imagine holding a broom stick with two weights at its ends. If you try rotating it, it will be hard to do. In this configuration it has a large moment of inertia. Now slide the weights in so that they are right next to your hand. It'll be much easier to rotate even though it still weighs the same. In this configuration it has a low moment of inertia.

It's important to build your Awana Grand Prix car with the smallest possible moment of inertia. Cars with large moments of inertia don't turn easily and when they do they use up a lot of energy, which causes the car to slow down. Cars with high moments of inertia also push against the guide rail harder and longer when they swerve into it. This creates more speed-robbing drag than a car with a low moment of inertia.

The key to building cars with the lowest possible moment of inertia is to concentrate as much of their weight as possible in as small an area as possible. Take a second look at the last picture. of its 98 grams, 89.1 grams are concentrated in the tungsten disk in the rear. This means almost all of its weight occupies a very small area so it will have a low moment of inertia. If I'd used lead the disk would have a larger diameter because it's less dense than tungsten and the car would have a slightly larger moment of inertia.

NEW FOR 2014!!! To determine if the increase in speed tungsten provides over lead is worth the $20 cost, I built a car where the primary weight could be swapped while maintaining the same overall weight of the car, the center of mass and aerodynamics. Two weights were compared. The first was a solid disc of lead 1.25 inches in diameter and the second a 1-inch diameter tungsten disk topped with a thin lead disk to bring its weight up to the same as the all lead weight. The moment of inertia of the lead disk was 50-percent larger than the tungsten and lead disk combination. The average of ten runs with the lead weight was 2.947 seconds. The average with the tungsten disk was 2.937 seconds. Tungsten's lower moment of inertia trimmed 0.010 seconds off the average run time. This equates to the tungsten car finishing 1.7 inches ahead of the lead weighted car. In the close races that finish a pinewood derby race, this is enough to be the difference between first place and last place. I leave it to the builder to decide if $20 is worth it. For myself it is.

The advantage of tungsten goes further than just reducing the moment of inertia. Because of its compactness compared to lead, it allows for smaller, more aerodynamically shaped bodies.

Having decided to use tungsten as the primary weight in my car's bodies, the next issue to address is what shape the additional lead should be. Tungsten disks weigh 92.5 grams. A high performance body weighs 9 grams. Wheels and axles another 11.5 grams. Finally, paint averages 1.2 grams. That totals 116 grams. To bring the finished car up to 141.7 grams means an additional 27.5 grams of lead must be added. Using the same weight-adjustable car, I compared the the average times for ten races each of the following four shapes:

Starting on the left is a lead ring that wrapped around the tungsten weight. This increases the moment of inertia, but creates the thinnest, most aerodynamically smooth body. Left center is a hemi-spherical weight glued to the top of the tungsten disk. Although it creates the highest profile and therefore drag, it creates the smallest moment of inertia. The flattened dome (right center) and smooth dome (far right) provide compromises between drag and moment of inertia.

With the ring the car averaged 2.994 second runs.

With the hemi-sphere it ran 2.985 seconds

The flattened dome and smooth dome both averaged 2.980 seconds and are the clear winners. Which one is to be preferred can be decided for cosmetic reasons.

One final test involved filling in the area immediately behind the spherical dome with ultra light weight filler and smoothing it to create what would seem to be a more aerodynamic shape. (The car's total weight was kept the same.) The result was a reduction in average run time of 0.002 seconds. This is within the uncertainty of the testing methodology so I can't make a conclusion on whether it helps. Since it doesn't hurt, and makes the car look better, I intend using it.

Axle Treatments:

Summary:

a.

Thorough polishing using 3600, 4000, 6000, 8000, 12,000 grit emery

cloths and rouge is important for the best times.

b.

Axle grooves don't make cars run faster.

c.

The hazards of hub coning

outweigh their benefits.

Axle

Polishing:

The vast majority of literature on pinewood cars recommends filing, sanding and polishing the axles to reduce friction between the axle and the wheel. As the close-up of a pinewood nail axle shows below, its extremely rough surface demands this sort of rough treatment:

The

typical nail provided in Boy Scout pinewood derby kits. Note the

uneven surface of

the

shaft and the flanges extending down from the head. All of these

have to be filed off

then

the shaft carefully sanded with a series of ever finer sandpapers

and finally polished

to

create a smooth enough surface to enable the car to run at top speed.

While

it's tempting to assume the same is true for Awana Grand Prix axles,

a close look at the hinge pins used suggests it may not be as important.

In

comparison, above is the hinge pin from an Awana Grand Prix car kit.

It has no

gross

shaft deformations or flanges hanging down from the head. Its

surface is so

smooth

that sanding and polishing may be considerably reduced.

(Both

images are 12X.)

To see if polishing is beneficial, I placed a wheel and axle set in a clamp and after applying graphite, finger spun the wheel 20 times, recorded how long the wheel spun and averaged the times to get 17.29 seconds. Then I sanded and polished the axle using 1500 grit sandpaper for two minutes followed by 6000 grit emery cloth for 10 minutes and then polishing with rouge for three minutes. I started with such a fine sandpaper because as the photo above shows, the largest surface defects are only slightly larger than the grit of 1500 paper. Using anything coarser would have made the surface rougher.

The resulting finish looked mirror smooth. I repeated the spin test being careful to apply the same amount of graphite in the same manner. The average of 20 spins was 18.69 seconds. The 1.4 second increase hardly seems worth the effort.

The problem with this and all other spin tests is that they test axle/bore combinations under effectively no-load conditions. An Awana Grand Prix race car wheel weighs 2.2 grams. In a well-balanced car the weight on each rear wheel is 60 grams. This means that under actual race conditions the load, and therefore drag, is 30 times that in spin tests. To determine if polishing provides any significant improvement under actual race conditions, I selected my grandson's fastest car and ran it down our track 10 times before polishing the axles then another 10 runs after they had been polished for one minute with 6000-grit emery cloth, then again after an additional minute of the emery cloth followed by one minute of polishing with rouge. Axle orientation was maintained for both tests to keep alignment constant so run times between axle changes varied less than 0.004 seconds. I was extremely careful to apply the same amount of the same type of graphite in the exact same manner before each test. Here are results:

Unpolished............

Polished

with Emery......

Polished

with Emery and Rouge

2.548

seconds......;.............2.541..................................2.528

2.563................................2.549..................................2.533

2.566................................2.545..................................2.529

2.577................................2.553..................................2.540

2.544................................2.539..................................2.526

2.552................................2.569..................................2.543

2.571................................2.536..................................2.532

2.565................................2.561..................................2.517

2.550................................2.559..................................2.510

2.546................................2.545..................................2.528

2.567 seconds average.........2.550 seconds average..........2.529 seconds average

This test shows that not only does polishing help significantly but that because Awana Grand Prix axles are very smooth to start with they don't require a lot of work to polish. Coarser sand papers such as those needed for BSA axle nails are not necessary.

A very good, straight axle benefits the most from polishing. A slightly out-of-true axle less so because its defects overpower the subtler benefits of polishing. The lesson is clear: always pick through your axle/wheel pairs to find the best. This is one case where spin testing is useful. If you only have two really good sets, put them in the rear of the car where the load is greatest. Finally, whitening toothpastes have extremely fine abrasives that are as effective as rouge for polishing.

Now that an advantage has been established for polishing, the next step is determining the polishing technique that provides the best finish with the least amount of work. The first question to address is: What is the best sand paper with which to begin the polishing process? Start with too coarse a grit and the axle will become rougher after the first sanding, necessitating a laborious succession of finer grits just to get back to original axle. Start with one that's too fine and you could waste enormous amounts of time and paper slowly grinding down the surface until the initial surface defects are eliminated. Unlike BSA axles, which come with gross surface defects and therefore demand coarse grits, Awana axles come from the factory with such a smooth finish that the starting point may be a very fine grit paper. To determine what a good starting grit is I used a sequence of grits on actual axles and photographed the effect of each grit after ten seconds of sanding with the axle chucked in a drill press. The following 100X images show the results:

1200

grit...............................................1800

grit.......................................................................2400

grit.......

3200

grit.........................................................................3600

grit...............................................................................4000

grit.......

6000

grit.........................................................................8000

grit...............................................................................12,000

grit

What

we need is the finest paper that eliminated most original surface

defects in a reasonable period of time. To my eye this appears to be

the 3600 grit paper. Experimentation determined that it takes 4

minutes with 4000 grit paper to completely eliminate surface defects.

After two minutes the paper quit cutting and a second piece had to be

used. The 3600 paper on a fresh axle achieved the same results in

only two minutes. After that, one minute each at 4000, 6000, 8000 and

12,000 followed by one minute with polishing rouge was sufficient to

complete the polish.

Comparing surface quality after using rouge and toothpaste showed that the toothpaste wasn't as smooth. But, it was very close so I would feel comfortable trusting in a toothpolish finish.

The next question is whether all this work is worth it? To answer that the following tests compare the run time for the same car on unpolished axles, axles lightly polished with two minutes of 6000 grit paper and one minute of toothpaste and finally axles thoroughly polished with 3600 grit for two minutes followed by 4000 through 12,000 papers for one minute each and finally Maximum Velocity's axle polishing compound for one minute. The car used was my grandson's newest creation:

Unpolished..................

Light Polish.....................

Thorough

Polish

2.657

seconds......;.............2.653..................................2.576

2.646................................2.619..................................2.603

2.698................................2.614..................................2.598

2.698................................2.621..................................2.604

2.694................................2.635..................................2.587

2.702................................2.692..................................2.618

2.694................................2.630..................................2.589

2.667................................2.623..................................2.639

2.689................................2.648..................................2.645

2.717................................2.645..................................2.631

2.681 seconds average....'....2.636 seconds average..'........2.609 seconds average

The 0.027 second advantage the thorough polishing provided over the light polishing is more than enough to justify the 10 minutes it takes to polish one axle.

Axle

Grooves:

A popular speed trick is to machine grooves into the axles to reduce the area in contact with the wheel and thereby reduce drag.

![]()

Pro

Speed axle from Maximum-Velocity.com

This

makes no sense to me because friction is the product of force

pushing two objects together and the coefficient of drag between

them. Since the force on a wheel, its share of the car's weigh, is

constant, all decreasing the area does is increase the force per unit

area or pressure. Because Awana plastic wheels are soft, this could

lead to deformation issues. To test the effectiveness of axle grooves

I spin tested an axle/wheel combination ten times and got an average

of 15.84 seconds. Next I chucked the axle in a drill press and used a

jeweler's file to carefully cut a shallow groove in it. The result

was that the spin test averaged 10.93 seconds, 4.91 seconds slower.

Thinking I'd done something wrong I repeated the test with a

professionally grooved axle (pro speed axle from

Maximum-velocity.com) and found that it too ran slower, averaging

12.87 seconds.

In both cases I observed that the wheel locked into a fixed position immediately after being spun. This suggests that the process of cutting a groove into an axle creates a sharp lip that acts as a guide to control the wheel and in so doing greatly increases drag. To test this hypothesis I polished the pro speed axle for one minute with 6000 emery cloth and then rouge, concentrating on the edges of the groove to remove any burs and soften the edge. Spin tests showed a significant improvement, up from 12.87 seconds to 18.50 seconds. I then polished the plain axle that generated the 15.84 time of the control test. After one minute of polishing with 6000 grit emery followed by rouge it had an average run time of 22.93 seconds.

These tests strongly suggest that contrary to popular belief, axle grooves do not reduce axle/bore drag. In fact they increase it. The following track tests with the Dale Sr. car verify this:

Regular

Shaft .........Pro

Speed Axle Polished as Directed

2.532

seconds............................2.551

2.533........................................2.559

2.534........................................2.540

2.552........................................2.563

2.545........................................2.548

2.537........................................2.574

2.525........................................2.561

2.519........................................2.550

2.527........................................2.541

2.532........................................2.551

2.534 seconds average.................2.549 seconds average

The

pro axles with grooves ran 0.015 seconds slower than regular

axles. This corresponds to finishing 2.3-inches behind a car

with Awana Grand Prix axles without grooves. I can offer no

explanation why so many references claim axle grooves reduce drag and

therefore increase speed while my experiments suggest otherwise.

Hub

Coning:

The

coned axle head on the right has had the outside 70-percent of the

head filed so that the

wheel

hub contacts it at a reduced radius. The red arrow indicated the

edge of the cone.

The

axle head in the right is of an unconed axle head.

Filing a cone into the inside head of the axle reduces the radius at which it can rub against the wheel hub. Assuming the force of drag is the same as for a full faced head, then the smaller radius means that there should be less torque to slow the wheel. The problem is that using a file to cut an angle on the inside face of the axle head is very dangerous. It's extremely easy to let the file drift in and score the axle. This would almost certainly result in tearing up the inside surface of the wheel bore and a subsequent loss of speed. To see if the benefit was worth the risk, I tested the same car before and after coning the axle heads.

Flat

Headed Axles . .............Coned

Axles

2.782

seconds............................2.788

2.764........................................2.789

2.777........................................2.763

2.776........................................2.764

2.736........................................2.750

2.747........................................2.731

2.754........................................2.743

2.752........................................2.745

2.789........................................2.751

2.757........................................2.734

2.763 seconds average...............'.2.758 seconds average

The

coned heads provided a 0.005-second advantage. However, considering

that the error associated with changing the axles is 0.004-seconds

it's difficult to say for certain if there is a significant advantage

to axle coning. Considering the risk of scoring the axle and the

requirement to polish the head after filing, I've decided this is not

a procedure I will use. For those wanting to do so, I recommend

wrapping the axle with tape before filing, sanding and polishing to

protect the shaft. If you're using nails, then since you'll be filing

everything anyway you might as well go ahead and cone the heads. It's

not important to polish the angled face of the cone because it never

comes in contact with the wheel hub. But it is necessary to highly

polish the line between the inner flat section of the face and the

start of the cone. Otherwise burs or the sharp edge itself could dig

into the wheel hub face. It takes five minutes to cone an axle head

and polish it. This can be reduced if the coning is accomplished with

axle polishing.

Axle

Straighteners:

These are two blocks of metal with a groove cut into each face. The axle to be straightened is placed in the groove, the two halves closed and the blocks struck with a hammer. If the grooves are straighter than the axle then the axle should come out straight. I've never used one of these and probably never will. None I've seen states that they are sized for Awana axle diameters, which are different than nail axles. If they were used on an Awana axle it's almost certain that flat spots or grooves would be hammered into the axle.

Wheel Treatments:

Summary:

a.

Avoid wheels with "14" stamped on them.

b.

Wheel mandrels can ruin wheels.

c.

Bore polishing doesn't

reduce drag.

d.

Coating wheel treads with graphite reduces

race times.

e.

Rim smoothing is a must-do operation.

f.

Coning the inner hub doesn't help.

g.

Always turn and polish

wheels, even professionally lathed wheels, if

you have an improved wheel mandrel.

h.

Wheel bore threading increases run times.

i.

If you have a drill press and an improved mandrel, lightly lathing

the outside wheel is a must-do operation.

"14"

Wheels:

Awana

wheels are modeled in sheets with each wheel numbered. Of the over 7

dozen wheels I've examined, those numbered "14" have bores

that are so small that they don't spin on the axles with one

exception, and even it dragged a little. If you're buying wheels and

are able to see the wheel numbers I recommend avoiding 14s.

Beware

of Wheel Mandrels:

Wheel mandrels come in two types: those with flat surfaces that bear against the wheel hub and those with one coned surface.

Flat-faced

wheel mandrel on the left, coned mandrel on the right.

Both

can ruin wheels. The problem with the flat type is that they are

loose enough that when a wheel is inserted into them it can end up

off center. While this doesn't affect tread smoothing, any attempt to

make the wheels rounder will almost certainly result in wheels that

are actually more out of round. Flat head mandrels are

useful for smoothing inside rims. Coned mandrels ensure the wheel is

centered but deform the edge of the hub bore by crushing the plastic

and in so doing create a inward facing rim that will make the wheel

run rough. I found it impossible to use a coned mandrel without doing

this. Tightening it enough to hold a wheel always creates enough

force to deform the plastic. Spin test of wheels before and after

using a coned mandrel resulted in a 4.65 second loss. The wheels ran

with a loud rattle that no amount of graphite could eliminate.

A problem with flat faced mandrels is that the two faces are textured. When tightened enough to hold a wheel this texturing gets pressed into the inner and outer wheelhub faces and could cause increased drag.

Wheel

Bore Polishing:

By coating a short length of pipe cleaner chucked into a drill with axle polish and running it through the bore of a wheel several times it's possible to polish the bore. In theory this should reduce drag and help the car run faster. The problem is that the bores of Awana Grand Prix wheels come out of the mold optically smooth. Any attempt to make them smoother could actually make them rougher. To determine if bore polishing helps I conducted the following track tests:

Unpolished

Bore.....................Polished

Bore

2.619

seconds...............................2.603

2.586...........................................2.618

2.599...........................................2.589

2.595...........................................2.599

2.585...........................................2.605

2.599...........................................2.631

2.600...........................................2.606

2.606...........................................2.596

2.631...........................................2.611

2.646...........................................2.625

2.607 seconds average...................'2.608 seconds average

The 0.001-second difference is too small to be significant considering that the error for identical sets of ten runs when axles are removed is 0.004-seconds. Therefore I'm concluding that bore polishing is not an effective investment in time.

Graphiting Wheels:

Coating wheel treads with graphite can reduce run times as much as 0.012 seconds, equivalent to a 2-inch lead at the finish line, as the following test results prove:

Uncoated

Wheel.....................Coated

Wheel

2.528

seconds...............................2.531

2.522...........................................2.509

2.528...........................................2.507

2.540...........................................2.525

2.526...........................................2.526

2.543...........................................2.522

2.532...........................................2.526

2.517...........................................2.501

2.510...........................................2.509

2.528...........................................2.514

2.529 seconds average....................2.517 seconds average

To coat wheels with graphite cover a sheet of paper with graphite and run the car over it several times until all four wheels have an even layer of graphite.

Spin the wheels two times to knock off loose powder that will dirty the track and make the track official give you an angry stare. The positive effect of graphiting wheels lasts a long time and in fact is difficult to remove once applied. An additional advantage is that it reduces the chances the soft plastic used in official Awana Grand Prix wheels picking up grit off the track. Roughening wheel surfaces from picking up debris is a major player in cars getting slower over time.

(I repeated this test two more times with different cars and the reduction in times were 0.002 seconds and 0.004 seconds so graphiting wheels may or may not be as significant advantage as the first test suggested. The older and rougher the wheels are the more this seems to help.)

The

Spin-up Myth:

Many sources claim that a car runs faster after it has been broken in for a dozen races. It's often recommended to use an electric drill to spin wheels to speed the breaking-in process. (In his DVD Physics and the Pinewood Derby, Dr. Acton presents experimental proof that this is not true and that in fact cars slow down the more they are raced. His exploration into this myth is extensive and touches on several other related issues that make it a must-have video.) My experiences suggest that the reason for this gradual slowing is roughening of the wheel tread and plastic from wheel bores becoming stuck to axles.

A similar myth is that graphite needs to get worked into the axle and hub for five races before the car runs its fastest times. An examination of 10 of the tests reported on this page should verify this. Consider the following tests reported earlier on this page and what the times indicate. Note that in each case the car's wheels were graphited before the first run.

Test 1...Test 2....Test 3 .TTest 4....Test 5....Test 6,,,,Test 7...Test 8,,,,Test 9...Test 10,,......,,Averages,

2.542

....2.531.....2.564.....2.544......2.542.....2.528.....2.531.....2.532.....2.551..,..2.528................2.539...

2.569.....2.563.....2.550.....2.528......2.554.....2.522.....2.509.....2.533.....2.559.....2.533................2.542....

2.558.....2.545.....2.537.....2.527......2.539.....2.528.....2.507.....2.534.....2.540.....2.529................2.534..

2.553.....2.557.....2.541.....2.532......2.533.....2.540.....2.525.....2.552.....2.563.....2.540................2.544...

2.564.....2.540.....2.547.....2.546......2.510.....2.526.....2.526.....2.545.....2.548.....2.526................2.538..

2.544.....2.564.....2.516.....2.559......2.535.....2.543.....2.522.....2.537.....2.574.....2.543................2.544..

2.547.....2.541.....2.529.....2.550......2.537.....2.532.....2.526.....2.525.....2.561.....2.532................2.538..

2.550.....2.560.....2.547.....2.570......2.542.....2.517.....2.501.....2.519.....2.550...,.2.517................2.537..

2.553.....2.551.....2.552.....2.561......2.541.....2.510.....2.509.....2.527.....2.541..,..2.510................2.536....

2.542.....2.553.....2.577.....2.551......2.547.....2.528.....2.514.....2.532.....2.551.....2.528................2.542...

........................................................................................................................................2.539 overall average

While

the averages for lines 7, 8 and 9 suggest a pattern of decreasing

run times, the high average time for line 10 and the fact that the

best time was run 3 indicates that this may only be an anomaly. For

myself, I plan on adding graphite to my cars immediately before

racing them. If there really is a breaking in period then you want to

save those runs for when competition is the hardest: the finals.

Early races are easier to get by so you want to save your best times

for the championship run.

Rim

Smoothing:

The

wheel on the right shows an inner rim as it comes from the factory.

Note the sharp edges and molding mark.

The

wheel on the left has been smoothed to remove molding marks and

given a rounded shape

to

help it glide along the guide rail.

As molded, Awana Grand Prix wheels come with rims that have very sharp edges that can snag and drag on the guide rail. By rounding and polishing this rim the wheel can slide along the guide rail more smoothly and in so doing lose less speed. The following test confirms this:

Unsmoothed

Rims . ...........Smoothed

Rims

2.731

seconds............................2.733

2.751........................................2.748

2.743........................................2.743

2.745........................................2.735

2.734........................................2.728

2.788........................................2.735

2.763........................................2.750

2.789........................................2.759

2.764........................................2.756

2.750........................................2.738

2.763

seconds average...............'.2.743

seconds average

The

0.020-second improvement equates to half a car-length lead at the

finish line. It also offers insurance against a track with defects in

the guide rail which could catch on the sharp edge of a wheel without

smoothed rims and flip it off the track. Clearly, rim smoothing is a

must-do operation.

Unfortunately it's not without risks and is a difficult process. I do it by mounting a wheel in a flat-headed mandrel in a drill press so that the rim faces up. The curve is roughed out using 150-grit sand paper. Then it's smoothed and polished using 220 to 6000 papers and rouge. I round both the inside and outside edges. Although it would seem that only the outside needs smoothing, when the car is running straight down the guide rail it's possible for the rim's inside edge to also come in contact with it. Be sure keep the sand paper wet at all times otherwise the wheel could heat up and melt.

The

risk of using a wheel mandrel is that if too much pressure is

applied to the sand paper the wheel may slip. If this happens the

threads on the mandrel's holding screw may score the wheel bore. It

takes five minutes to properly smooth and polish one wheel rim. This

reduces to almost zero if it's accomplished in conjunction with wheel

tread polishing.

Inner

Wheel Hub Coning:

The purpose of rounding or coning the inside hub is to reduce the radius at which it rubs the car's body, thereby reducing the resulting drag torque, and to polish it smoother for the same reason. I'm not a fan of this procedure because I've only measured a marginal improvement in race times. Add to this the difficulty of working this area smoothly (the wheel can't be chucked in a drill press and still permit access to the inner wheel hub) and the risk of sand paper grit getting into the bore and destroying not only the wheel but the axle as well and it is my opinion that this is a procedure with more risks than are justified by the advantages. Besides, if a drill press is used to drill axle holes and the chuck pressed down onto the wood the chuck jaws will polish a smooth cone into the wood, creating the same effect much easier.

Wheel

Turning,

Polishing and Graphiting:

Most references warn against turning wheels at home to make them round because without a lathe you can do more damage that good. That's absolutely true if you attempt it using wheel mandrels and hand-held cutters. But, if you have a drill press, a razor blade and a block of wood I believe the average person can turn a wheel accurately enough to improve run times. Here's how:

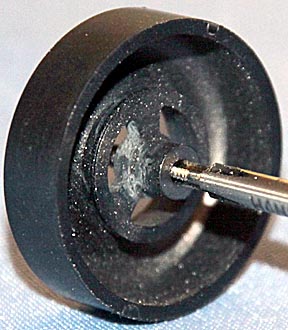

"Turning" refers to the process of rotating almost-round objects against a cutting tool to remove the high points and in so doing make the object more circular. In the case of a Awana Grand Prix wheel, or any pinewood derby wheel, removing the high points that make a wheel out of round is like sanding off speed bumps on the track. If the wheel has a high spot, then during every revolution that high spot is going to bump the car up ever so slightly and in so doing slow it down. Because wheel mandrels can hold wheels off center, using one can result in making the wheel more lopsided that it was before turning it. Fortunately, the hub on the inside of the wheel of Awana Grand Prix wheels is long enough for the jaws in a drill press's chuck to grab. Every wheel I've inspected has the bore concentric with the outside of the hub so chucking onto the hub allows the wheel to be properly turned.

To begin, secure the wheel in the drill press by chucking onto the hub. Only use finger tightness. Using a chuck key could tighten the jaws so much that they crush the hub. Next, secure a one-sided razor blade on a block of wood. With the wheel spinning at the press's medium speed, slowly easy the razor blade toward the wheel so that it barely touches it.

Always

make sure that the wheel is turning away from the blade.

If

the blade is pointing into the direction of spin it will jam into

the

wheel, destroy it, and could very likely injure you.

Always

wear protection equipment.

Keep the amount of blade extending out from the block as short as possible or the metal's springiness will cause it to chatter, resulting is a series of closely spaced high and low points much like washboard on a dirt road. (This is also why simply holding the blade in your hand doesn't work.) At first you'll hear the blade "clicking" as it hits only the highest points. Always being safe and careful, experiment with different cutting angles to see which works best for you. As the blade's moved in, it will wear down the high points and the action will become smoother. It usually only takes 20 seconds to turn a wheel. It's not necessary to grind the wheel all the way down, just take off the high points so that when the wheel is stopped you can see a thin zone showing wear all the way around the wheel. This zone may meander across the tire's face, but as long as it's the same radius relative to the bore the wheel will run smoothly.

After turning the wheel, sand and polish it. I found a good starting point is 1000-grit sandpaper followed by 1500, 3600, 4000, 6000, 8000, 12,000 (Always wet the paper so the wheel doesn't melt.) and finally polishing compound on a strip of cloth. It only takes 20 seconds at each stage; figure 3 minutes per wheel.

After that you might want to finish by graphiting the wheels. Some references recommend using plastic polish. I prefer not to because the polish leaves a microscopic layer that could pick up and hold debris. Graphite doesn't seem to do this.

The following track tests show the effect of turning, polishing and graphiting:

Unturned

Wheel.....................Turned

Wheel

2.770

seconds...............................2.741

2.756...........................................2.743

2.744...........................................2.758

2.746...........................................2.723

2.768...........................................2.748

2.765...........................................2.730

2.754...........................................2.752

2.747...........................................2.752

2.756...........................................2.718

2.745...........................................2.751

2.755 seconds average....................2.742 seconds average

The 0.013-second improvement is well worth the work.

Turned

and Polished.....Turned,

Polished and Graphited

2.707

seconds...............................2.695

2.694...........................................2.712

2.741...........................................2.722

2.741...........................................2.719

2.720...........................................2.722

2.716...........................................2.730

2.728...........................................2.722

2.724...........................................2.730

2.719...........................................2.720

2.715...........................................2.700

2.721 seconds average....................2.717 seconds average

Polishing is a clear winner though the 0.004-second advantage from graphiting is just barely enough to recommend it. I suspect that polishing performs the same function of smoothing, which is why adding graphite to polished wheel isn't as effective as it is with rough wheels.

Further experimentation lead me to a product called Novus 2, a liquid fine scratch remover made specifically for plastic. I found it created a much smoother finish than the rouge I had been using. It's so effective that sanding can stop after 3600-grit paper followed by one minute of Novus 2 on a strip of cloth. The resulting tread is beautifully shiny.

Turning increases speed by allowing the wheels to run smoother. Why polishing and graphiting wheel treads helps is more of a mystery. One possibility is that the wheels inevitably move back and forth across the axles. As they do so they must slide on the track. Reducing the coefficient of friction of the wheel-track interface allows them to slide with less drag so they don't use up as much of the car's speed.

Important: Always use a cotton swab to wipe all grit and polishing compound off the inside of the wheel followed by blowing out the inside, outside and in particular the wheel bore before inserting an axle. Grit from the polishing process sticks to the wheel and if it falls into the bore it can score both it and the axle.

An

Improved Wheel Mandrel: